Freeze Drying Machine (Dryer for Drugs in Injection Vials)

As a professional vacuum freeze dryer manufacturer in China, our company has been involved in producing freeze drying machine for drugs filled in vials for over 20 years and our drug freeze drying machines conform to the modified GMP certification.

Features

1. Our freeze drying machines are designed in models with nominal freeze-drying area ranging from 5m2 to 42m2. They are suitable for the lyophilization of most of the drugs filled in vials.

2. The dryer for drugs in injection vials we produce is able to automatically recognize the time when the freeze drying process is finished.

3. After the freeze drying processing cycle is finished, the lyophilization equipment will enter into CIP and SIP process automatically.

Composition of Freeze Drying Machine

Our company is a pharmaceutical freeze dryer supplier in China and the pharmaceutical freeze drying machine we produce is composed of the following components.

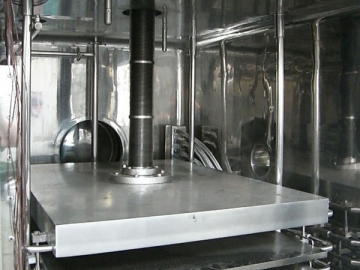

Drying Cabinet of Freeze Drying Machine

The drying cabinet of our pharmaceutical freeze drying machine is designed in accordance with the GB150-2011/PED/ASME standard and it conforms to the requirements of CGMP and FDA. The drying cabinet has a polished mirror-like inside and an inclined bottom, facilitating water discharging in the CIP and SIP processes.

Cold Trap of Freeze Drying Machine

The cold trap used in our pharmaceutical freeze dryer employs the direct expansion refrigeration principle. Our cold trap can be vertical or horizontal. Reasonable design of the water vapor channel allows the molecules to move more smoothly with smaller resistance. The valve between the drying cabinet and the cold trap can achieve recognition of the finishing of the freezing-drying process.

The cold trap can be designed to support CIP and SIP. It can also be used for cooling the tank of large pharmaceutical freeze dryer after SIP.

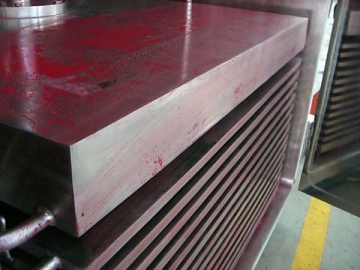

Shelf of Freeze Drying Machine

The shelf of our pharmaceutical freeze drying equipment adopts indirect refrigeration method and can also be heated to supply power for the products to sublimate. The shelf spacing of our large pharmaceutical freeze dryer is adjustable to make it applicable for placing vials of various heights.

Vacuum System ofFreeze Drying Machine

The vacuum system which is made up of vacuum pumps or roots pumps is mainly used for building up vacuum and expelling gases. The air intake port of every vacuum pump is assembled with an automatic stop valve preventing gas backflow. The vacuum gauge assembled to our pharmaceutical freeze dryer is MKS capacitive gauge or Edwards Pirani vacuum gauge.

SIP System of Freeze Drying Machine

The SIP system of our pharmaceutical freeze dryer adopts the impulse forvacuum steam sterilizing method and is equipped with an FO displaying & recording device. This SIP system has complete interlocking function. In the steam inlet manifold there is a pneumatic controlled steam master valve. Inside the SIP system there is a safety valve which can relief automatically when the working pressure exceeds the designed pressure. The tank not only has its own cooling system, but also has pressure and temperature protection devices. When the pressure or temperature is higher than the preset value, the protection devices will work automatically to turn off the steam inlet valve and turn on the air release valve. The dual protection devices guarantee the SIP system of our lyophilizer works safely.

Circulation System ofFreeze Drying Machine

The circulation system which uses circulating pumps to achieve forced circulation of the secondary refrigerant is mainly used to achieve hot and cold energy exchange between refrigerating medium and secondary refrigerant; secondary refrigerant and shelf; shelf and the product to be freeze-dried.

CIP System of Freeze Drying Machine

The CIP system of our freeze drying machine accords with the FDA/CGMP standard. This system consists of a CIP workstation and is designed with no dead corners. Our CIP system can achieve steam sterilization and the pipelines are welded with trajectory welding technology.

Hydraulic System ofFreeze Drying Machine

The hydraulic pump station and oil cylinder are mounted on the top of the drying cabinet. Powdered by the hydraulic pumps, the oil cylinder drives the shelf to move up and down stably. Sealing units of the oil cylinder include Y-fluororubber, O-luororubber and dust prevention assembling units. The components of the hydraulic pump are from internationally famous manufacturers. Stainless steel corrugated pipes can be fitted to the outside of the hydraulic rod.

Refrigeration System of Freeze Drying Machine

The refrigeration system of our pharmaceutical freeze dryer is mainly composed of the refrigeration compressor, water condenser, expansion valve, plate evaporator, oil separator, etc. The main machine of the refrigeration system adopts imported two-stage semi-hermetic compressor or screw compressor. Each compressor works as an independent refrigeration circulation system and freeze the shelf and the cold trap through plate heat exchanger and condenser pipe respectively. The pipeline of the refrigeration system is well engineered and accurately installed to ensure the whole refrigeration system is able to run efficiently and stably for a long period of time.

Our refrigeration system is designed to have adequate energy to cope with the vapor produced in sublimation. This refrigeration system also come with many protection functions such as motor over-temperature protection, overload protection, high pressure protection, low pressure protection, medium pressure protection, oil pressure difference protection, and cooling water low level protection.

Control System of Freeze Drying Machine

We adopt PID control mode to control the temperature of the shelf and the vacuum degree of our freeze drying machine to achieve quick freeze, slow freeze, repeated freeze and constant temperature keeping.

d. Output Module e. Input Module f. Temperature Control Module g. Communication Module

h. AD Module i. CPU Module j. Power Supply Module

Software of Freeze Drying Machine

The intelligent control software used for our pharmaceutical freeze dryer is internationally advanced configuration software which is developed based on the terminal and remote control technology. The intelligent control software has the functions of PID control, automatic monitoring and freeze-drying formula management. As a set of industrial software dedicated for vacuum freezing drying equipment, it also supports multi-language operation and remote control.

- Parameter setting

- Processing curve programming

- Defrosting

- Full-automatic running

- Data recording

Parameters of Freeze Drying Machine

| Parameters | Unit | GLZY-B (CIP) Freeze Drying Machine | GLZY-BS (CIP SIP) Freeze Drying Machine | ||||||||||

| Nominal area | 1 | 2 | 3 | 5 | 7.5 | 1 | 2 | 3 | 5 | 7.5 | |||

| Capacity | Effective shelf area | m2 | 1.08 | 2.16 | 3.24 | 4.86 | 7.56 | 1.08 | 2.16 | 3.24 | 4.86 | 7.56 | |

| Condenser capacity | kg/B | 20 | 40 | 60 | 100 | 150 | 20 | 40 | 60 | 100 | 150 | ||

| Vial quantity | Φ16mm | piece | 4100 | 8200 | 12300 | 18450 | 30750 | 4100 | 8200 | 12300 | 18450 | 30750 | |

| Φ22mm | piece | 2100 | 4200 | 6300 | 9450 | 15750 | 2100 | 4200 | 6300 | 9450 | 15750 | ||

| Liquid capacity of tray | L | 20 | 40 | 60 | 100 | 150 | 20 | 40 | 60 | 100 | 150 | ||

| Basic parameters | Shelf size | Width | mm | 450 | 600 | 600 | 900 | 900 | 450 | 600 | 600 | 900 | 900 |

| Length | mm | 600 | 900 | 900 | 900 | 1200 | 600 | 900 | 900 | 900 | 1200 | ||

| Shelf spacing | mm | 100 | |||||||||||

| Shelf quantity | layer | 4 1 | 4 1 | 6 1 | 6 1 | 7 1 | 4 1 | 4 1 | 6 1 | 6 1 | 7 1 | ||

| Shelf temperature range | ℃ | -55~ 80 | |||||||||||

| Shelf temperature difference | ℃ | ±1.0 (Balanced) | |||||||||||

| Lowest temperature of cold trap | ℃ | ≤-75 | |||||||||||

| Final vacuum degree | Pa | ≤1 | |||||||||||

| Basic kit supply | Cooling water consumption: ≤30℃, 0.15~0.2MPa | m3/hr | 3.2 | 4.2 | 4.5 | 11 | 16 | 3.2 | 4.2 | 4.5 | 11 | 16 | |

| Cleaning water consumption: CIP-WIP: ≥65℃, 0.15~0.2MPa | L/min | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | ||

| Pure steam consumption for SIP: 0.2-0.3MPa | kg/hr | 20 | 40 | 60 | 100 | 150 | |||||||

| Steam consumption for defrosting: 0.2-0.3MPa | kg/hr | 5 | 10 | 15 | 25 | 40 | |||||||

| Compressed air consumption: 0.6-1.0MPa | m3/min | 0.1 | |||||||||||

| Water consumption for defrosting: ≈50℃, 0.1-0.2MPa | kg/B | 270 | 270 | 300 | 400 | 1200 | |||||||

| Installation power: 400V, 3P5W, 50Hz (±5%) | kW | 9 | 12 | 21 | 24 | 44 | 9 | 12 | 21 | 24 | 44 | ||

| Total weight | t | 1.9 | 2.3 | 2.8 | 4.2 | 6 | 2 | 2.6 | 3.8 | 4.5 | 8.2 | ||

| Overall dimension | Length | mm | 3100 | 3510 | 4470 | 4790 | 5320 | 3230 | 3640 | 4600 | 4930 | 5460 | |

| Width | mm | 1180 | 1340 | 1340 | 1740 | 1740 | 1500 | 1620 | 1620 | 2020 | 2020 | ||

| Height | mm | 2550 | 2550 | 2800 | 3100 | 3200 | 2550 | 2550 | 2800 | 3100 | 3200 | ||

| Nominal area | Unit | 1 | 2 | 3 | 5 | 7.5 | 1 | 2 | 3 | 5 | 7.5 | ||

| 200mm-300mm If the pharmaceutical freeze dryer is fitted with a corrugated pipe protective sleeve, the total height of the freeze drying equipment will increase by 200~300mm. | |||||||||||||

| Parameters | Unit | GLZY-B (CIP) Pharmaceutical Freeze Dryer | GLZY-BS (CIP SIP) Pharmaceutical Freeze Dryer | ||||||||||||||||

| Nominal area | 10 | 13 | 15 | 20 | 25 | 30 | 40 | 50 | 10 | 13 | 15 | 20 | 25 | 30 | 40 | 50 | |||

| Capacity | Effective area of shelf | m2 | 9.72 | 12.96 | 16.1 | 19.67 | 25.0 | 31.5 | 42 | 51.0 | 9.72 | 12.96 | 16.1 | 19.67 | 25.0 | 31.5 | 42 | 51.0 | |

| Condenser capacity | kg/B | 200 | 260 | 320 | 400 | 500 | 600 | 800 | 1000 | 200 | 260 | 320 | 400 | 500 | 600 | 800 | 1000 | ||

| Vial quantity | Φ16mm | piece | 38950 | 51250 | 65600 | 83160 | 102500 | 118900 | 164000 | 205000 | 38950 | 51250 | 65600 | 83160 | 102500 | 118900 | 164000 | 205000 | |

| Φ22mm | piece | 19950 | 26250 | 33600 | 42900 | 52500 | 60900 | 84000 | 105000 | 19950 | 26250 | 33600 | 42900 | 52500 | 60900 | 84000 | 105000 | ||

| Liquid capacity of tray | 200 | 260 | 300 | 400 | 500 | 600 | 800 | 1000 | 200 | 260 | 300 | 400 | 500 | 600 | 800 | 1000 | |||

| Basic parameters | Shelf size | Width | mm | 900 | 1200 | 1200 | 1200 | 1200 | 1490 | 1490 | 1490 | 900 | 1200 | 1200 | 1200 | 1200 | 1490 | 1490 | 1490 |

| Length | mm | 1200 | 1200 | 1490 | 1490 | 1490 | 1490 | 1990 | 1990 | 1200 | 1200 | 1490 | 1490 | 1490 | 1490 | 1990 | 1990 | ||

| Shelf spacing | mm | 100 | 90 | 100 | 90 | ||||||||||||||

| Shelf quantity | layer | 9 1 | 9 1 | 9 1 | 11 1 | 14 1 | 14 1 | 14 1 | 17 1 | 9 1 | 9 1 | 9 1 | 11 1 | 14 1 | 14 1 | 14 1 | 17 1 | ||

| Shelf temperature range | ℃ | -55~ 80 | |||||||||||||||||

| Shelf temperature difference | ℃ | ±1.0 (Balanced) | |||||||||||||||||

| Lowesttemperature of cold trap | ℃ | ≤-75 | |||||||||||||||||

| Final vacuum degree | Pa | ≤1 | |||||||||||||||||

| Basic kit supply | Cooling water consumption: ≤30℃, 0.15~0.2MPa | m3/hr | 18 | 20 | 20 | 20 | 38 | 38 | 50 | 50 | 18 | 20 | 20 | 20 | 38 | 38 | 50 | 50 | |

| Cleaning water consumption: CIP-WIP: ≥65℃, 0.15~0.2MPa | L/min | 100 | 100 | 100 | 150 | 200 | 200 | 200 | 200 | 100 | 100 | 100 | 150 | 200 | 200 | 200 | 200 | ||

| Pure steam consumption for SIP: 0.2-0.3MPa | kg/hr | 200 | 260 | 300 | 400 | 500 | 550 | 600 | 650 | ||||||||||

| Steamconsumption for defrosting: 0.2-0.3MPa | kg/hr | 50 | 65 | 75 | 100 | 125 | 150 | 200 | 250 | ||||||||||

| Compressed air consumption: 0.6-1.0MPa | m3/min | 0.1 | |||||||||||||||||

| Water consumption for defrosting: ≈50℃, 0.1-0.2MPa | kg/B | 1300 | 1400 | 1700 | 1900 | 2500 | 6000 | 8000 | 10000 | ||||||||||

| Installation power: 400V, 3P5W, 50Hz (±5%) | kW | 58 | 67 | 75 | 104 | 125 | 134 | 174 | 210 | 58 | 67 | 75 | 104 | 125 | 134 | 174 | 210 | ||

| Total weight | t | 7 | 8 | 9 | 12.5 | 13 | 18 | 20 | 25 | 8.6 | 9 | 12 | 18 | 20 | 25 | 28 | 35 | ||

| Overall dimension | Length | mm | 5300 | 5530 | 5850 | 6810 | 7020 | 7560 | 8080 | 8350 | 5440 | 5680 | 6000 | 6950 | 7160 | 7700 | 8220 | 8490 | |

| Width | mm | 1740 | 2050 | 2050 | 2050 | 2050 | 2450 | 2450 | 2450 | 2016 | 2316 | 2316 | 2316 | 2316 | 2716 | 2716 | 2716 | ||

| Height | mm | 3420 | 3450 | 3450 | 4100 | 4250 | 4310 | 4350 | 4960 | 3420 | 3450 | 3450 | 4100 | 4250 | 4310 | 4350 | 4960 | ||

| Nominal area | Unit | 10 | 13 | 15 | 20 | 25 | 30 | 40 | 50 | 10 | 13 | 15 | 20 | 25 | 30 | 40 | 50 | ||

| The total height of the lyophilization equipment will increase by 200mm~300mm if a corrugated pipe protective sleeve is fitted. | |||||||||||||||||||