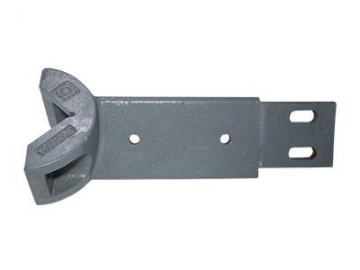

High Chrome Iron Wear Resistant Castings

Chromium’s excellent wear resistance, toughness, heat and corrosion resistance ensure that high chrome iron castings are ideal for use in construction equipment, mining equipment, cement mixers, coal washing equipment, water pumps, and more as the casting pumps. Due to their excellent wear resistance, the service life and productivity are both increased.

We are an expert manufacturer of high chrome castings, and are outfitted with a complete line of production equipment, allowing us to offer our customers the best chrome iron castings at the most competitive prices to meet an extensive array of customer needs.

KMTBGR2

KMTBGR8

KMTBGR12

KMTBGR15MO

KMTBGR20MO

KMTBGR26

GB/T8263-1999

Why choose us- Reasonable Chemical Composition

With the exception of common elements, precious metal is added as an alternative. Equipped with accurate analyzer, we are able to quickly detect and adjust the chemical content as needed to meet custom requirements. - Advanced Metallurgy Technique

A medium-frequency induction furnace is used for all castings to prevent any impurities and toxic gases from influencing the purity of molten iron and preventing segregation. - Strict Temperature Controlling

The best temperature control criteria has been developed based on our extensive experience, and inspectors carry out a strict quality control of each step to ensure the final quality. - Advanced Casting Technique

An advanced EPC casting process ensures the cast products feature fine grains and a dense structure. - Advanced Heat Treating

Several heat treating furnaces are responsible for annealing, normalizing and tempering to eliminate internal stress, prevent deformation, and increase product strength.

Zhuangzhi has devoted to custom wear resistant castings for more than 10 years. Currently the yield has reached up to 20,000 tons per year. These products have been widely serving in cement mixer truck, asphalt mixer, asphalt paver, crusher and other industry equipment. Upon your requirements against abrasion, impact, corrosion or heat, specific material will be chose to manufacture your wear resistant castings. And followings are the links to other castings.