PCBN Blanks

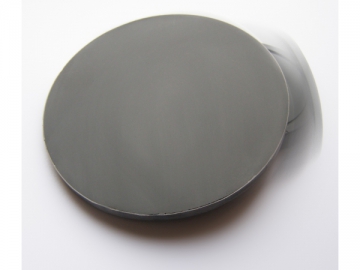

PCBN Blank

Description

The PCBN blank has the advantages of high hardness, highthermo stability, high chemical stability, good strength and good weld ability. The PCBN cutting tool can realize highspeed cutting, hard material cutting and dry cutting. It can precisely process the products and replace grinding with turning. The PCBN cutting tool meets the requirements of environmentalprotection.

Our PCBN blank is manufactured by world famous companies such as Element Six (DeBeers), DI (GE), ILJIN, SMITH,SUMITOMO and TOMEI. We also offer laserengraving service of PCBN blank.

Features

1. The PCBN blank features high hardness and high abrasive resistance. The hardnessof PCBN blank is 3,000HV to 5,000HV. Theabrasive resistance of PCBN cutting tool is 50 times that of hard alloy cuttingtool, 30 times that of coating hard alloy cutting tool and 25 times that ofceramic cutting tool.

2. The PCBN blank has high thermo stability and heat resistance. The heat resistance of PCBN cutting tool canreach 1400 to

3. The PCBN blank has high chemical stability. With high oxidation resistance, PCBN cutting toolwill not be oxidized under the temperature of

4. The PCBN blank features good thermal conductivity. Its thermal conductivity is lower thandiamond but it is higher than tungstencarbide.

5. The PCBN has low friction coefficient. The friction coefficient of PCBN is 0.1 to0.3, while that of tungstencarbide is 0.4 to 0.6.

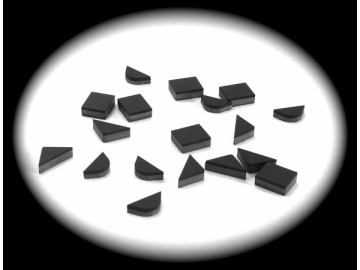

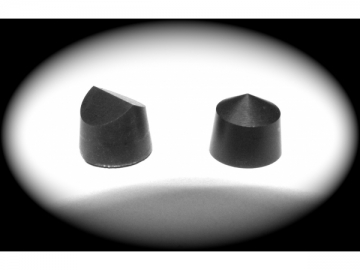

Application

The PCBN blank applies tovarious ferrous metals, such as cast iron, nodular cast iron, pearlite castiron, hardened steel, bearing steel, tungstencarbide, roller, and sintered alloy.

Technical Specifications

| Specification of PCD Blank (Discs) | ||||

| Company | Model | Dimension (mm) Diameter • Thickness | Grain Size (μm) | PCD Layer Thickness (mm) |

| Element Six (E6) | CTB002 | ¢74x1.6/2.0/3.18 | 2μm | 0.3/0.5/0.7 |

| CTB010 | ¢74x1.6/2.0/3.18 | 10μm | 0.3/0.5/0.7/1.0 | |

| CTH025 | ¢74x1.6/2.0/3.18 | 25μm | 0.5 | |

| CTM302 | ¢74x1.6/2.0/3.18 | 30μm 2μm | 0.5/0.7/1.5 | |

| SUMITOMO | DA90 | ¢64x1.6/2.0/3.18 | 50μm | 0.5 |

| DA150 | ¢64x1.6/2.0/3.18 | 5μm | 0.5 | |

| DA200 | ¢64x1.6/2.0/3.18 | 0.5μm | 0.5 | |

| DA2200 | ¢64x1.6/2.0/3.18 | 0.5μm | 0.5 | |

| GE (DI) | GE1600 | ¢58x1.6/2.0/3.18 | 4μm | 0.5 |

| GE1300 | ¢58x1.6/2.0/3.18 | 5μm | 0.5 | |

| GE1500 | ¢58x1.6/2.0/3.18 | 25μm | 0.5 | |

| GE1800 | ¢58x1.6/2.0/3.18 | 25μm 4μm | 0.5 | |

| SMITH | M10 | ¢58x1.6/2.0/3.18 | 10μm | 0.5 |

| AMX | ¢58x1.6/2.0/3.18 | 9μm | 0.5 | |

| F05 | ¢58x1.6/2.0/3.18 | 5μm | 0.5 | |

| C30X | ¢58x1.6/2.0/3.18 | 30μm | 0.5 | |

| ILJIN | CC | ¢60x1.6/2.0/3.18 | 25μm | 0.5 |

| CM | ¢60x1.6/2.0/3.18 | 10μm | 0.5 | |

| CF | ¢60x1.6/2.0/3.18 | 4μm | 0.5 | |

| CXL | ¢60x1.6/2.0/3.18 | 25μm | 0.5 | |

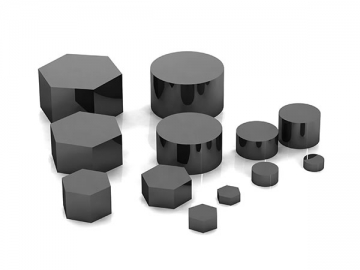

Material

The PCBN blank uses CBN powder and tungsten carbide.

Packaging

The PCBN blank is packaged in a plasticcase.

World is a PCBN blank manufacturer and supplier, based in