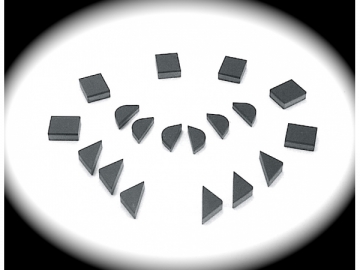

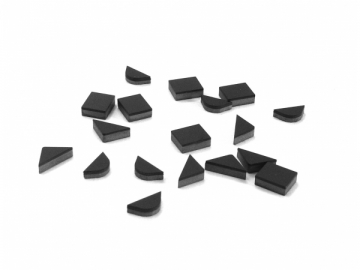

PCD Blanks

PCD Blank

Description

The PCD blank has the advantages of high hardness,high abrasive resistance, high thermal conductivity, low friction coefficient,low heat expansion coefficient, good strength and toughness. It can realize high speed cutting, hard materialcutting and high precision processing. The PCD blank meets the requirement of environmental protection.

Our PCD blank is manufactured by world famous companies such as Element Six (DeBeers), DI (GE), ILJIN, SMITH,SUMITOMO and TOMEI. We also offer laser engravingservice of PCBN blank.

Features

1. The hardness of PCD reaches 8000HV, which is 80 to 120 times that of tungstencarbide.

2. The thermal conductivity of PCD is 1.5 to 9 times that of tungstencarbide, and itis even higher than that of PCBN and copper. Its thermal conductivity is 700W/mK. The PCD blank cantransfer heat fast.

3. The friction coefficient of PCD is only 0.1 to 0.3, while that of tungstencarbide is 0.4 to 1. The PCD cutting toolfeatures small cutting force.

4. The heat expansion coefficient of PCD is 0.9×10-6 to 1.18×10-6, which isonly one fifth that of tungstencarbide. The PCDcutting tool features small thermal deformation and high processingprecision.

5. The affinity between the PCD cutting tool and the materials, includingnonferrous metal and nonmetal materials, is small. The cuttings will not attach to the toolduring processing.

Application

The PCD blank is used in many different fieldsincluding aviation, the car industry, electronics, and the wood and stoneindustry. It applies to various materials such as nonferrous metal, tungstencarbide, ceramic, nonmetal and composite material.

| Materials to be Processed | Products | |

| Nonferrous Metal | Aluminum, Aluminum alloy | Piston, cylinder, wheel hub, transmission case, pump body, admission pipe and various shell parts for cars and motorcycles. |

| Tank body, shell and compressor parts for airplanes and electro mechanical products. | ||

| Precision machinery parts for cameras, duplicators and metrical instruments. | ||

| Parts for pump body and oil press. | ||

| Copper, Copper Alloy | Axle, bearing bush, bearing and pump body for internal combustion engines and ships. | |

| Parts for various instruments, dynamo commutators, printed boards and electronic apparatus. | ||

| Bearing, bearing bush, valve and shell body. | ||

| tungstencarbide | Sinter such as valve seat and cylinder, and semi-finished sinter. | |

| Others | Various nonferrous metal parts such as magnesium and zinc. | |

| Nonmetal | Wood | Hardwood, artificial board, artificial abrasion resistant fiberboard. |

| Reinforced Plastic | Glass fiber and carbon fiber reinforced plastic. | |

| Rubber | Roller for paper and rubber ring. | |

| Graphite | Carbon rod. | |

| Ceramic | Sinter such as sealing ring and plunger piston, and semi-finished sinter. | |

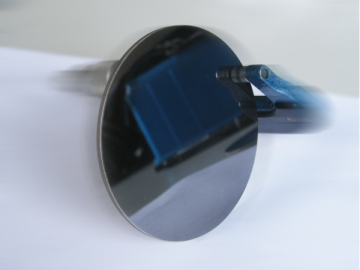

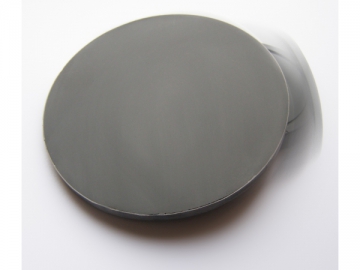

Technical Specifications

| Specification of PCD Blank (Discs) | ||||

| Company | Model | Dimensions (mm) Diameter x Thickness | Grain Size (μm) | PCD Layer Thickness (mm) |

| Element Six (E6) | CTB002 | ¢74x1.6/2.0/3.18 | 2μm | 0.3/0.5/0.7 |

| CTB010 | ¢74x1.6/2.0/3.18 | 10μm | 0.3/0.5/0.7/1.0 | |

| CTH025 | ¢74x1.6/2.0/3.18 | 25μm | 0.5 | |

| CTM302 | ¢74x1.6/2.0/3.18 | 30μm 2μm | 0.5/0.7/1.5 | |

| SUMITOMO | DA90 | ¢64x1.6/2.0/3.18 | 50μm | 0.5 |

| DA150 | ¢64x1.6/2.0/3.18 | 5μm | 0.5 | |

| DA200 | ¢64x1.6/2.0/3.18 | 0.5μm | 0.5 | |

| DA2200 | ¢64x1.6/2.0/3.18 | 0.5μm | 0.5 | |

| GE (DI) | GE1600 | ¢58x1.6/2.0/3.18 | 4μm | 0.5 |

| GE1300 | ¢58x1.6/2.0/3.18 | 5μm | 0.5 | |

| GE1500 | ¢58x1.6/2.0/3.18 | 25μm | 0.5 | |

| GE1800 | ¢58x1.6/2.0/3.18 | 25μm 4μm | 0.5 | |

| SMITH | M10 | ¢58x1.6/2.0/3.18 | 10μm | 0.5 |

| AMX | ¢58x1.6/2.0/3.18 | 9μm | 0.5 | |

| F05 | ¢58x1.6/2.0/3.18 | 5μm | 0.5 | |

| C30X | ¢58x1.6/2.0/3.18 | 30μm | 0.5 | |

| ILJIN | CC | ¢60x1.6/2.0/3.18 | 25μm | 0.5 |

| CM | ¢60x1.6/2.0/3.18 | 10μm | 0.5 | |

| CF | ¢60x1.6/2.0/3.18 | 4μm | 0.5 | |

| CXL | ¢60x1.6/2.0/3.18 | 25μm | 0.5 | |

Material

The PCD blank uses diamond powder and tungsten carbide.

Packaging

Plastic case

World is a PCD blank manufacturer and supplier, based in