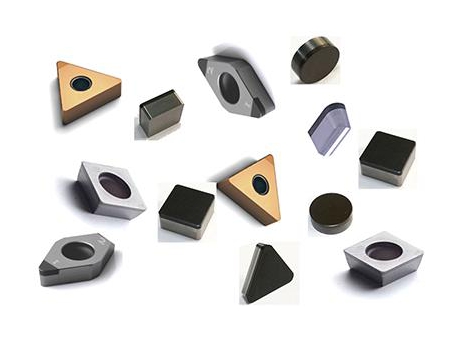

PCBN Inserts

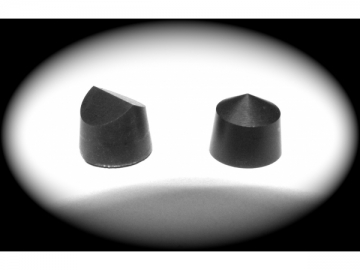

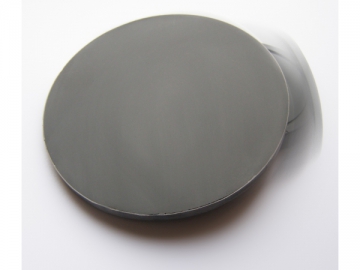

PCBN Insert

Features

1. The PCBN insert meets the international standard of ISO.

2. The PCBN insert has the advantages of high abrasive resistance, highprocessing precision, good thermalconductivity and long service life.

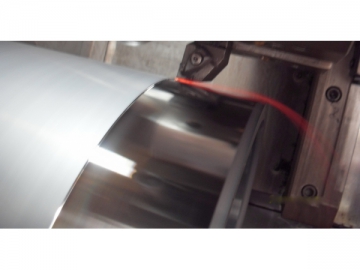

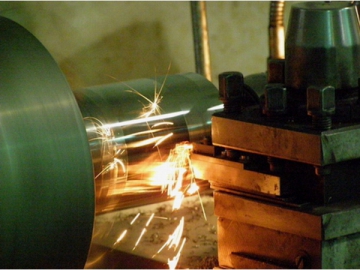

3. The PCBN insert can realize high speed cuttingand hard material cutting with high work efficiency.

4. The PCBN insert can facilitate fast clamping.

5. The PCBN insert can be used repeatedly so it can lower your processing cost.

Application

The PCBN insert is used to process hardened steel,hardened cast iron, grey cast iron and iron series metal work pieces.

Technical Specifications

| Model | Dimension (mm) | ||||

| L | C | s | d | R | |

| VNGA160404 | 16.6 | 9.525 | 4.76 | 3.81 | 0.4 |

| VNGA160408 | 16.6 | 9.525 | 4.76 | 3.81 | 0.8 |

| VNGA160412 | 16.6 | 9.525 | 4.76 | 3.81 | 1.2 |

| VBGW160404 | 16.6 | 9.525 | 4.76 | 4.4 | 0.4 |

| VBGW160408 | 16.6 | 9.525 | 4.76 | 4.4 | 0.8 |

| DCGW11T302 | 11.6 | 9.525 | 3.97 | 4.4 | 0.2 |

| DCGW11T304 | 11.6 | 9.525 | 3.97 | 4.4 | 0.4 |

| DCGW11T308 | 11.6 | 9.525 | 3.97 | 4.4 | 0.8 |

| DNGA150404 | 15.5 | 12.7 | 4.76 | 5.16 | 0.4 |

| DNGA150408 | 15.5 | 12.7 | 4.76 | 5.16 | 0.8 |

| DNGA150412 | 15.5 | 12.7 | 4.76 | 5.16 | 1.2 |

| DNGN150404 | 15.5 | 12.7 | 4.76 | ☆ | 0.4 |

| DNGN150408 | 15.5 | 12.7 | 6.35 | ☆ | 0.8 |

| DNGN150412 | 15.5 | 12.7 | 6.35 | ☆ | 1.2 |

| TNGA160402 | 16.5 | 9.525 | 4.76 | 3.81 | 0.2 |

| TNGA160404 | 16.5 | 9.525 | 4.76 | 3.81 | 0.4 |

| TNGA160408 | 16.5 | 9.525 | 4.76 | 3.81 | 0.8 |

| TNGA160412 | 16.5 | 9.525 | 4.76 | 3.81 | 1.2 |

| TCGW090202 | 9.6 | 5.56 | 2.38 | 2.5 | 0.2 |

| TCGW090204 | 9.6 | 5.56 | 2.38 | 2.5 | 0.4 |

| TCGW090208 | 9.6 | 5.56 | 2.38 | 2.5 | 0.8 |

| TCGW110204 | 11.0 | 6.35 | 2.38 | 2.8 | 0.4 |

| TCGW110208 | 11.0 | 6.35 | 2.38 | 2.8 | 0.8 |

| TCGW16T304 | 16.5 | 9.525 | 3.97 | 4.3 | 0.4 |

| TCGW16T308 | 16.5 | 9.525 | 3.97 | 4.3 | 0.8 |

| TPGB090204 | 9.6 | 5.56 | 2.38 | 2.5 | 0.4 |

| TPGB090208 | 9.6 | 5.56 | 2.38 | 2.5 | 0.8 |

| TNGN110302 | 11.0 | 6.35 | 3.18 | ☆ | 0.2 |

| TNGN110304 | 11.0 | 6.35 | 3.18 | ☆ | 0.4 |

| TNGN110308 | 11.0 | 6.35 | 3.18 | ☆ | 0.8 |

| TPGN110302 | 11.0 | 6.35 | 3.18 | ☆ | 0.2 |

| TPGN110304 | 11.0 | 6.35 | 3.18 | ☆ | 0.4 |

| TPGN110308 | 11.0 | 6.35 | 3.18 | ☆ | 0.8 |

| CNMA120404 | 12.9 | 12.7 | 4.76 | 5.16 | 0.4 |

| CNMA120408 | 12.9 | 12.7 | 4.76 | 5.16 | 0.8 |

| CNMA120412 | 12.9 | 12.7 | 4.76 | 5.16 | 1.2 |

| CNMA120416 | 12.9 | 12.7 | 4.76 | 5.16 | 1.6 |

| CCGW060202 | 6.4 | 6.35 | 2.38 | 2.8 | 0.2 |

| CCGW060204 | 6.4 | 6.35 | 2.38 | 2.8 | 0.4 |

| CCGW060208 | 6.4 | 6.35 | 2.38 | 2.8 | 0.8 |

| CCGW080202 | 8.0 | 7.94 | 2.38 | 3.4 | 0.2 |

| CCGW080204 | 8.0 | 7.94 | 2.38 | 3.4 | 0.4 |

| CCGW080208 | 8.0 | 7.94 | 2.38 | 3.4 | 0.8 |

| Model | Dimension (mm) | ||||

| L | C | s | d | R | |

| TNGA160402 | 16.5 | 9.525 | 4.76 | 3.81 | 0.2 |

| TNGA160404 | 16.5 | 9.525 | 4.76 | 3.81 | 0.4 |

| TNGA160408 | 16.5 | 9.525 | 4.76 | 3.81 | 0.8 |

| TNGA160412 | 16.5 | 9.525 | 4.76 | 3.81 | 1.2 |

| TCGB090204 | 9.6 | 9.56 | 2.38 | 2.5 | 0.4 |

| TCGB090208 | 9.6 | 9.56 | 2.38 | 2.5 | 0.8 |

| SNGA09T302 | 9.525 | 9.525 | 3.97 | 4.4 | 0.2 |

| SNGA09T304 | 9.525 | 9.525 | 3.97 | 4.4 | 0.4 |

| SNGA090316 | 9.525 | 9.525 | 3.18 | 3.81 | 1.6 |

| SNGA060202 | 6.35 | 6.35 | 2.38 | 2.8 | 0.2 |

| SNGA060204 | 6.35 | 6.35 | 2.38 | 2.8 | 0.4 |

| SNGA060208 | 6.35 | 6.35 | 2.38 | 2.8 | 0.8 |

| SCGW090304 | 15.5 | 12.7 | 4.76 | 5.16 | 0.4 |

| SCGW090308 | 15.5 | 12.7 | 4.76 | 5.16 | 0.8 |

| SCGW090316 | 15.5 | 12.7 | 4.76 | 5.16 | 1.6 |

| SCGW120404 | 12.7 | 12.7 | 4.76 | 5.5 | 0.4 |

| SCGW120408 | 12.7 | 12.7 | 4.76 | 5.5 | 0.8 |

| SCGW120412 | 12.7 | 12.7 | 4.76 | 5.5 | 1.2 |

| SPGN090304 | 9.525 | 9.525 | 3.18 | ☆ | 0.4 |

| SPGN090308 | 9.525 | 9.525 | 3.18 | ☆ | 0.8 |

| SPGN090312 | 9.525 | 9.525 | 3.18 | ☆ | 1.2 |

| SNGN150408 | 15.5 | 12.7 | 4.76 | 5.16 | 0.8 |

| SNGN150412 | 15.5 | 12.7 | 4.76 | 5.16 | 0.8 |

| SNGN190412 | 15.5 | 12.7 | 4.76 | 5.16 | 1.2 |

| SPGN090308 | 9.525 | 9.525 | 3.18 | ☆ | 0.8 |

| SPGN120408 | 12.7 | 12.7 | 4.76 | ☆ | 0.8 |

| SPGN120412 | 12.7 | 12.7 | 4.76 | ☆ | 1.2 |

| SPGN150404 | 15.875 | 15.875 | 4.76 | ☆ | 0.8 |

| SPGN150412 | 15.875 | 15.875 | 4.76 | ☆ | 1.2 |

| HEEN090408 | ☆ | 15.92 | 4.76 | ☆ | 0.8 |

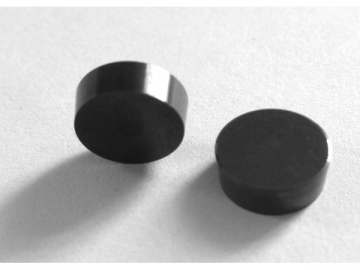

Specification of Solid PCBN Insert

| Model | Dimension (mm) | |

| ISO | ΦD | S |

| RNMA251000 | 25.4 | 10 |

| RNMA201000 | 20 | 10 |

| RNMA200700 | 20 | 7.94 |

| RNMA150700 | 15.875 | 7.94 |

| RNMA12T600 | 12.7 | 6.80 |

| RNMA120400 | 12.7 | 4.76 |

| RNMA090400 | 9.525 | 4.76 |

| RNMA080400 | 8.5 | 4.76 |

| Model | Dimension (mm) | ||

| ISO | ΦD | S | r |

| RCMN12T600 | 12.7 | 6.8 | 0 |

| RCMN150700 | 15.875 | 7.94 | 0 |

| RCMN190700 | 19.05 | 7.94 | 0 |

| Model | Dimension (mm) | |||

| ISO | L | ΦD | S | R |

| SNMN120408 | 12.7 | 12.7 | 4.76 | 0.8 |

| SNMN12T612 | 12.7 | 12.7 | 6.8 | 1.2 |

| SNMN150720 | 15.875 | 15.875 | 7.94 | 2.0 |

| SNMN201020 | 20 | 20 | 10 | 2.0 |

Material

The tool bit uses PCBN blanks manufactured by world famous companiesincluding Element Six (DeBeers, E6), DI (GE), ILJIN, SMITH, SUMITOMO andTOMEI. The body part uses high quality tungsten carbide.

World is a PCBN insert manufacturer and supplier, based in