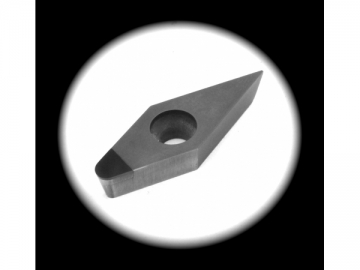

PCD Milling Tools

PCD Milling Tool

Description

PCD blanks feature high hardness, high abrasiveresistance, high thermal conductivity and strong toughness. The PCD milling tool has advantages over the averagehard alloy milling tool.

Features

1. The PCD milling tool features high processingprecision and high processing efficiency.

2. The PCD milling tool can realize high speed cutting and hard materialcutting.

3. With the features of high abrasive resistance and thermal conductivity, PCDmilling tool has a long service life. Its service life is 10 to 20 times that of a hardalloy milling tool.

Application

The PCD milling tool is used to process work pieces ofvarious materials, including copper, aluminum, copper alloy, aluminum alloy andcomposite material. It can be used to process cast aluminum alloy enginecase.

Technical Specifications

| Dimension (mm) | |||

| ΦD | L | L1 | Er |

| 4 | 100 | 55 | 120 |

| 6 | 100 | 55 | 120 |

| 8 | 100 | 55 | 120 |

| 10 | 100 | 55 | 120 |

| 12 | 120 | 55 | 120 |

| 14 | 150 | 55 | 120 |

Material

The tool bit of the PCD milling tools uses PCD blanks manufactured by worldfamous companies including Element Six (DeBeers, E6),DI (GE), ILJIN, SMITH, SUMITOMO and TOMEI. The body part uses high quality tungstencarbide and tool steel.

World is a PCD milling tool manufacturer and supplier, based in