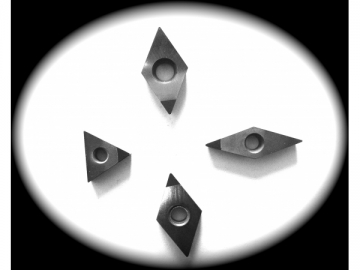

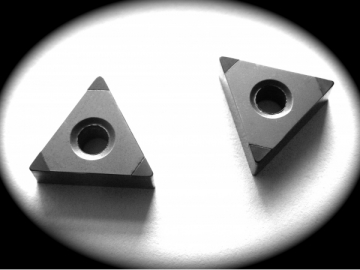

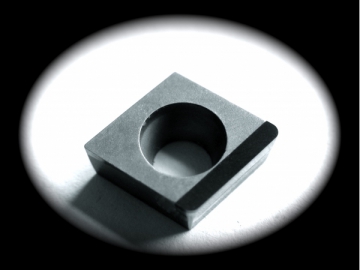

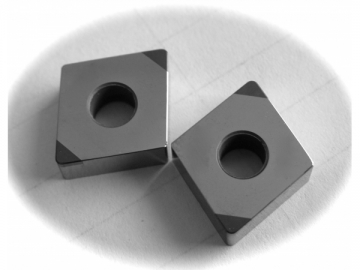

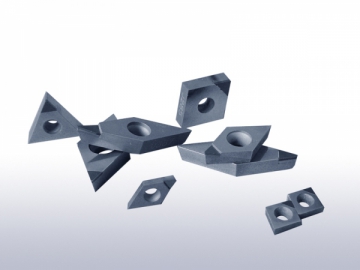

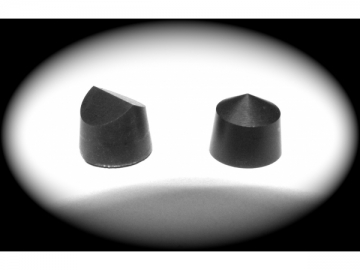

PCD Inserts

PCD Insert

Features

1. The PCD insert meets the international standard of ISO.

2. The PCD insert has theadvantages of high abrasive resistance, high processing precision, good thermal conductivity and long service life.

3. The cutting edge is sharp.

4. The PCD insert can realize high speed cutting and hard material cutting withhigh work efficiency.

5. The PCD insert can facilitate fast clamping.

6. The PCD insert can be used repeatedly, which helps to lower your processingcost.

Application

The PCD insert can be used in many fieldsincluding aviation, the car industry, energy equipment, and the woodand stone industry. It can be used to cut and process different materials such as nonferrous metal, tungsten carbide,ceramic, nonmetal and composite material.

| Materials to be Processed | Products | |

| Nonferrous Metal | Aluminum, Aluminum Alloy | Piston, cylinder, wheel hub, transmission case, pump body, admission pipe and various shell parts for cars and motorcycles. |

| Tank body, shell and compressor parts for airplanes and electro mechanical products. | ||

| Precision machinery parts for cameras, duplicators and metrical instruments. | ||

| Parts for pump body and oil press. | ||

| Copper, Copper Alloy | Axle, bearing bush, bearing and pump body for internal combustion engines and ships. | |

| Parts for various instruments, dynamo commutators, printed boards and electronic apparatus. | ||

| Bearing, bearing bush, valve and shell body. | ||

| tungsten carbide | Sinter such as valve seat and cylinder, and semi-finished sinter. | |

| Others | Various nonferrous metal parts such as magnesium and zinc. | |

| Nonmetal | Wood | Hardwood, artificial board, artificial abrasion resistant fiberboard. |

| Reinforced Plastic | Glass fiber and carbon fiber reinforced plastic. | |

| Rubber | Roller for paper and rubber ring. | |

| Graphite | Carbon rod. | |

| Ceramic | Sinter such as sealing ring and plunger piston, and semi-finished sinter. | |

Technical Specifications

| Model | Dimension (mm) | ||||

| L | C | s | d | R | |

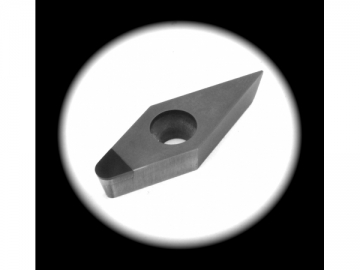

| VCMT110302 | 11.1 | 6.35 | 3.18 | 2.8 | 0.2 |

| VCMT110304 | 11.1 | 6.35 | 3.18 | 2.8 | 0.4 |

| VCMT110308 | 11.1 | 6.35 | 3.18 | 2.8 | 0.8 |

| VCMT160404 | 16.6 | 9.525 | 4.76 | 4.4 | 0.4 |

| VCMT160408 | 16.6 | 9.525 | 4.76 | 4.4 | 0.8 |

| VCMT160412 | 16.6 | 9.525 | 4.76 | 4.4 | 1.2 |

| VNMA160402 | 16.6 | 9.525 | 4.76 | 3.81 | 0.2 |

| VNMA160404 | 16.6 | 9.525 | 4.76 | 3.81 | 0.4 |

| VNMA160408 | 16.6 | 9.525 | 4.76 | 3.81 | 0.8 |

| VNMA160412 | 16.6 | 9.525 | 4.76 | 3.81 | 1.2 |

| DCMT070202 | 7.7 | 6.35 | 2.38 | 2.8 | 0.2 |

| DCMT070204 | 7.7 | 6.35 | 2.38 | 2.8 | 0.4 |

| DCMT070208 | 7.7 | 6.35 | 2.38 | 2.8 | 0.8 |

| DCMT11T302 | 11.6 | 9.525 | 3.97 | 4.4 | 0.2 |

| DCMT11T304 | 11.6 | 9.525 | 3.97 | 4.4 | 0.4 |

| DCMT11T308 | 11.6 | 9.525 | 3.97 | 4.4 | 0.8 |

| DNMA150404 | 15.5 | 12.7 | 4.76 | 5.16 | 0.2 |

| DNMA150408 | 15.5 | 12.7 | 4.76 | 5.16 | 0.8 |

| DNMA150412 | 15.5 | 12.7 | 4.76 | 5.16 | 1.2 |

| TNMA160404 | 16.5 | 9.525 | 4.76 | 3.81 | 0.4 |

| TNMA160408 | 16.5 | 9.525 | 4.76 | 3.81 | 0.8 |

| TNMA160412 | 16.5 | 9.525 | 4.76 | 3.81 | 1.2 |

| CNMA120404 | 12.9 | 12.7 | 4.76 | 5.16 | 0.4 |

| CNMA120408 | 12.9 | 12.7 | 4.76 | 5.16 | 0.8 |

| CNMA120412 | 12.9 | 12.7 | 4.76 | 5.16 | 1.2 |

| CCMT060202 | 6.4 | 6.35 | 2.38 | 2.8 | 0.2 |

| CCMT060204 | 6.4 | 6.35 | 2.38 | 2.8 | 0.4 |

| CCMT060208 | 6.4 | 6.35 | 2.38 | 2.8 | 0.8 |

| CCMT09T302 | 9.7 | 9.525 | 3.97 | 4.4 | 0.2 |

| CCMT09T304 | 9.7 | 9.525 | 3.97 | 4.4 | 0.4 |

| CCMT09T308 | 9.7 | 9.525 | 3.97 | 4.4 | 0.8 |

| WNMA080404 | 8.7 | 12.7 | 4.76 | 5.16 | 0.4 |

| WNMA080408 | 8.7 | 12.7 | 4.76 | 5.16 | 0.8 |

| WNMA080412 | 8.7 | 12.7 | 4.76 | 5.16 | 1.2 |

| Model | Dimension (mm) | ||||

| L | C | s | d | R | |

| SNMA060202 | 6.35 | 6.35 | 2.38 | 2.8 | 0.2 |

| SNMA060204 | 6.35 | 6.35 | 2.38 | 2.8 | 0.4 |

| SNMA060208 | 6.35 | 6.35 | 2.38 | 2.8 | 0.8 |

| SNMA070202 | 7.94 | 7.94 | 2.38 | 3.4 | 0.2 |

| SNMA070204 | 7.94 | 7.94 | 2.38 | 3.4 | 0.4 |

| SNMA070208 | 7.94 | 7.94 | 2.38 | 3.4 | 0.8 |

| SNMA09T302 | 9.525 | 9.525 | 3.97 | 4.4 | 0.2 |

| SNMA09T304 | 9.525 | 9.525 | 3.97 | 4.4 | 0.4 |

| SNMA09T308 | 9.525 | 9.525 | 3.97 | 4.4 | 0.8 |

| SNMA060204 | 6.35 | 6.35 | 2.38 | 2.8 | 0.4 |

| SNMA070202 | 7.94 | 7.94 | 2.38 | 3.4 | 0.2 |

| SNMA09T301 | 9.525 | 9.525 | 3.97 | 4.4 | 0.1 |

| SNMA09T302 | 9.525 | 9.525 | 3.97 | 4.4 | 0.2 |

| SNMA09T304 | 9.525 | 9.525 | 3.97 | 4.4 | 0.4 |

| SPGN090302 | 9.525 | 9.525 | 3.18 | ☆ | 0.2 |

| SPGN090304 | 9.525 | 9.525 | 3.18 | ☆ | 0.4 |

| SPGN090308 | 9.525 | 9.525 | 3.18 | ☆ | 0.8 |

| SPGN120304 | 12.7 | 12.7 | 3.18 | ☆ | 0.4 |

| SPGN120308 | 12.7 | 12.7 | 3.18 | ☆ | 0.8 |

| SPGN120312 | 12.7 | 12.7 | 3.18 | ☆ | 1.2 |

| SNGN090302 | 9.525 | 9.525 | 3.18 | ☆ | 0.2 |

| SNGN090304 | 9.525 | 9.525 | 3.18 | ☆ | 0.4 |

| SNGN090308 | 9.525 | 9.525 | 3.18 | ☆ | 0.8 |

| SNGN120304 | 12.7 | 12.7 | 3.18 | ☆ | 0.4 |

| SNGN120308 | 12.7 | 12.7 | 3.18 | ☆ | 0.8 |

| SNGN120312 | 12.7 | 12.7 | 3.18 | ☆ | 1.2 |

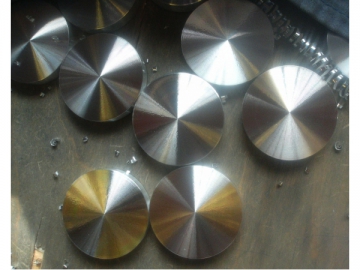

Material

The tool bit uses PCD blanks manufactured by world famous companies including ElementSix (DeBeers, E6), DI (GE), ILJIN, SMITH,SUMITOMO and TOMEI. The body part useshigh quality tungsten carbide.

World is a PCD insert manufacturer and supplier, based in