Horizontal Form Fill Seal Machine, DXD-130

Request a Quote

The DXD-130 horizontal form fill seal machine automatically packages liquid, powder, or granular products into single or double sachets. This sealing machine can perfectly seal the bottom, sides, and top of the bagged product for a standing pouch. With PLC control, the pouch packaging line moves efficiently from bagging the powdered, liquid, or granular product to packing the bags into boxes or cartons. This automatic packaging machine, designed to prevent corrosion, features a glass cover which prevents dust from escaping.

Main performance parameters

- Capacity: ≤60 pouches/min

- Pouch size: Width: 60-130mm, Height: 80-180mm

- Volume: 200ml

- Precision: ±1%

- Inner diameter: Φ70-80mm

- Outer diameter: ≤Φ500mm

- Air pressure: 0.5-0.7MPA

- Power source: Three phase AC380V, 50HZ

- Power: 3.5KW

- External dimensions: 2580 x 945 x 1550mm(L x W x H)

- Weight: 1350KG

Machine Details

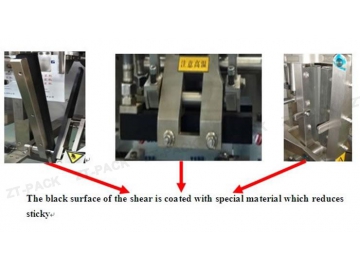

- Special Coating

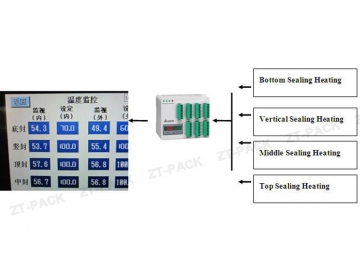

Sealing components and shears and rods are specially coated to prevent growing sticky over time. - Smart Temperature Control System

The temperature of each heating block is controlled and by PLC. Adjustments can easily and quickly be done via touch screen, and PLC control provides dependable and consistent operations. - Imported Electrical Components

Main components such as the PLC, touch screen, servo system, frequency converter, and power switch, are from Schneider. Photo electricity system, vacuum, coders and magnetic braker are from Omron, SMC, SUNX, Convum, and OPTEX in Japan as well as KEB from Germany. Our transformer has passed CE, TUV, and ISO9001 certification. - Connecting Rod

The connecting rod is made of SUS304 casting instead of welding for higher stability.

Features

- Used for packaging, food, pesticides, pharmaceutical drugs, fertilizers, and other products, whether in liquid, powder or granular form through simple setting adjustments.

- Frequency control system uses an imported motor for stable and reliable operation.

- Servo feeding system controls the feeding screw for fast and stable conveying.

- Pouch system: Filling and sealing pouches happen separately to easily adjust settings.

- Product packaging system uses heat-sealing packaging material (polyethylene film, MLCM) to automatically measure, fill, seal, and bag products. Finished products are in a standing bag.

- Integrated control system uses PLC for high control and reliable operation from one project to the next. Photoelectric sensor, coder, and proximity switch protect the product and machine.

- Servo pulling bag system uses PLC positioning for high accuracy and a large torque for pulling speed.

Configuration

| No. | Name | Origin | Brand |

| 1 | Contactor | France | Schneider |

| 2 | Thermal | France | Schneider |

| 3 | Circuit Breaker | France | Schneider |

| 4 | Frequency Convertor | France | Schneider |

| 5 | Button | France | Schneider |

| 6 | PLC | France | Schneider |

| 7 | Servo System | France | Schneider |

| 8 | Servo Motor | France | Schneider |

| 9 | Power Switch | France | Schneider |

| 10 | Fan | Taiwan | SUNON |

| 11 | Sensor | Japan | SUNX |

| 12 | Proximity Switch | South Korea | Autonics |

| 13 | Encoder | Japan | Omron |

| 13 | Magnetic Braker | Germany | KEB |

| 15 | Vacuum Ejector | Japan | Convum |

Bag samples