Horizontal Form Fill Seal Machine, DXD-110

The DXD-110 horizontal form fill seal machine automatically packages liquid, powder, or granular products into single or double sachets. This sealing machine can perfectly seal the bottom, sides, and top of the bagged product for a standing pouch. With PLC control, the pouch packaging line moves efficiently from bagging the powdered, liquid, or granular product to packing the bags into boxes or cartons. This automatic packaging machine, designed to prevent corrosion, features a glass cover which prevents dust from escaping.

| Packing material | Complex film |

| Packing products | Powder, liquid, granule, solid |

| Production speed | 40-80pm |

| Precision | Within /-1% |

| Pouch width | 50 -110mm |

| Pouch height | 50 -120mm |

| Max. volume | 60ml |

| Electricity consumption | 2kw |

| Air consumption | 0m 3 /min |

| Voltage | 380 V 50Hz |

| Weight | 600 kg |

| Size | 2060mm * 750mm * 1400mm |

- Used for packaging, food, pesticides, pharmaceutical drugs, fertilizers, and other products, whether in liquid, powder or granular form through simple setting adjustments.

- Frequency control system uses an imported motor for stable and reliable operation.

- Servo feeding system controls the feeding screw for fast and stable conveying.

- Pouch system: Filling and sealing pouches happen separately to easily adjust settings.

- Product packaging system uses heat-sealing packaging material (polyethylene film, MLCM) to automatically measure, fill, seal, and bag products. Finished products are in a standing bag.

- Integrated control system uses PLC for high control and reliable operation from one project to the next. Photoelectric sensor, coder, and proximity switch protect the product and machine.

- Servo pulling bag system uses PLC positioning for high accuracy and a large torque for pulling speed.

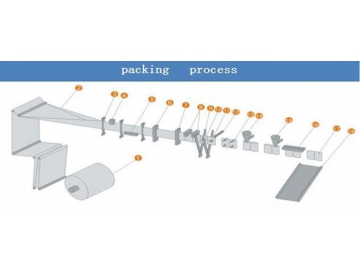

1. Film unwind

2. Bag forming

3 Film guide

4. Photocell

5. Bottom seal

6. First vertical seal

7. Second vertical seal

8. Tear notch

9. Double cutting

10. Pouch catching

11. Pouch catching

12. Pouch pulling

13. Pouch opening

14. Filling I

15. Filling II

16. Top Seal

17/18. Finished Product Outlet

| No. | Name | Origin | Brand |

| 1 | Contactor | France | Schneider |

| 2 | Thermal | France | Schneider |

| 3 | Circuit Breaker | France | Schneider |

| 4 | Frequency Convertor | France | Schneider |

| 5 | Button | France | Schneider |

| 6 | PLC | France | Schneider |

| 7 | Servo System | France | Schneider |

| 8 | Servo Motor | France | Schneider |

| 9 | Power Switch | France | Schneider |

| 10 | Fan | Taiwan | SUNON |

| 11 | Sensor | Japan | SUNX |

| 12 | Proximity Switch | South Korea | Autonics |

| 13 | Encoder | Japan | Omron |

| 13 | Magnetic Braker | Germany | KEB |

| 15 | Vacuum Ejector | Japan | Convum |