Automated Warehouse System

A Warehouse Management System (WMS) is a combination of software and processes that enables organizations to efficiently control and manage warehouse operations—from the moment goods or materials enter the warehouse until they are shipped out. Key operations within a warehouse include inventory management, picking and packing processes, and auditing.

The smart four way shuttle robot is a versatile, high tech packaging and storage equipment piece capable of performing four direction conveying, in-place rail changing, automatic transferring, intelligent monitoring, and dynamic transportation management.

- Storage area in intelligent workshop

- Smart warehouse for compact finished products/semi-finished products\raw materials

- Warehouse in logistic transfer center

- Unmanned warehouse

| Model | ||||||

| Rated load capacity | 0.8 T | 1.2 T | 1.0 T | 1.5 T | 1.5 T | 2.0 T |

| No-load speed | 1.2 m/s | 1.0 m/s | 1.5 m/s | 1.2 m/s | 1.2 m/s | 0.8 m/s |

| Full-load speed | 1.0 m/s | 1.2 m/s | 1.2 m/s | 1.0 m/s | 1.0 m/s | 1.2 m/s |

| undefinedLoad surfacelength | 1200-1400mm | 1200-1400mm | 1200-1400mm | 1200-1400mm | 1600-2100mm | 1600-2100mm |

| Load surfacewidth | 800-1200mm | 800-1200mm | 800-1200mm | 800-1200mm | 800-1600mm | 800-1600mm |

| Thickness | 247mm | 247mm | 180mm | 180mm | 180mm | 180mm |

| Power supply | 48V/40AH | 48V/40AH | 48V/40AH | 48V/20AH | 48V/40AH | 48V/20AH |

| Duration | 6-8h | 2-3h | 6-8h | 2-3h | 6-8h | 2-3h |

| Charge mode | Automatic charging | |||||

- Integrated Storage and Transferring

Smart four-way shuttle robot can moves under the cargo and change rail in-place at the rail crossing. It can transfer the goods from storage location to designated location at one time, with no secondary handling.

- Intelligent Dynamic Transportation Management

Smart shuttle robot has its own control system and built-in warehouse map, which enables the automatic recording and feedback of information, autonomous optimization and updating of routines, as well as real-time feedback of storage space and equipment status.

- Modular Configuration

The inside control parts adopt modular and pluggable design, easy for changing and maintenance.

- Compact Storage

Single-layer storage layout realizes the combination of different deep bits and provides optimal storage solutions for the complicated quality and specifications of goods.

- Three-dimensional Layout

Based on different warehouse heights and good heights, different storage layers can be designed. Three-dimensional smart compact storage is also available even in low storage region.

- Expansibility

The amount of adopted equipment can be adjusted according to the inbound and outbound efficiency. The existing project can be expanded later under the premise of not affecting the using, which features short construction period.

Special hoist for shuttle robot is a new type conveying appliance, specially designed for lifting goods and layer changing of smart four-way shuttle robot. It is able to transfer materials vertically and continuously, ensuring that shuttle robots in different layers can maintain continuous logistic transportation.

- Single-way, two-way and three-way hoist is available based on actual conditions.

- Modular assembly mode greatly saves the design space.

- This hoist can interface with both shuttle robot and goods, providing high transfer efficiency and suitable for high speed convey.

- It can match the conveying equipment to make the whole conveying process fully automatic, avoiding the instability from manual operation.

- The terminal can communicate with the warehouse control software WCS without hindrance, integrating the whole production process. It is also helpful to incorporate the temporary storage zone, production area, storage and transfer system, facilitating the production planning and information transfer.

| Weight | 2.0 T |

| Max. Load capacity | 2.5T |

| Speed | ≥0.6 m/s |

| Size | Customizable based on customer needs |

| Positioning mode | Bar code |

| Positioning accuracy | ±5mm |

| Control mode | Vector frequency conversion |

| Operating temperature | -30℃~45℃ |

Warehouse control system adopts WCS WMS system information interactive mode, capable of managing and driving all the semi-automatic and automatic equipment in the warehouse including logistic robot, lifting machine, conveyor system, forklit, camera system, etc. WCS human-computer interface can timely display real-time status and task execution of every equipment. Operators can operate intuitively within competence extent.

- Real-time update and visual management of equipment and good allocation.

- Control system supports task ranking setting, task issuing in batches and automatic outbound after optimization.

- Control system enables flexible scheduling and cooperative working of multi-devices.

- Platform-level control is available. Simultaneous remote-monitoring of multiple WCS platform is realizable.

Warehouse management system can provide product storage strategy, set the warehousing process, manage storage of goods, efficiently follow up and control the logistics and cost of the whole warehouse business, and achieve perfect warehouse informatization management. It can also interface with ERP and MES system to exchange data and provide comprehensive information on enterprise business process and financial management.

- Inbound and outbound services

- Warehouse allotting

- Virtual warehouse management

- Integrated batch management

- Three-dimensional goods allocation

- Stocktaking

- Real-time stock control

- Seamless interface

- Warehouse management system supports multi levels of management on warehouse, zone, good allocation, etc. It also provides batch management about warehouse goods and supports several unit of measurement, allowing automatic conversion of different units.

- Warehouse management system can record the current amount of stock goods and historical information, as well as the searching the historical records of inbound and outbound goods of any previous stage.

- Stocktaking, adjustment of inventory shortage and overage are available.

- Mluti-condition inquiry can be carried out to get comprehensive and first-hand inventory information.

- Warehouse management system can interface with EPR, MRP and WCS software, helping to improve the depth and breadth of business management.

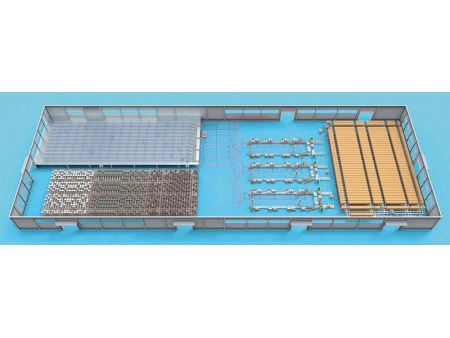

Based on customers’ actual demands and existing informatization platform, IVEN realizes informatization, standardization, visualization, intelligence and automation of warehouse management by adding hardware and deepening message scheduling. Smart compact storage system is supported by informatization platform and hardware facilities, gives priority to inbound and outbound goods and material transfer. This achieves flexible scheduling of storage, conveying, information, personnel and other sources and realizes intelligent operation and management of factory.

Smart internal logistic system is a new smart conveyor system designed based on our previous technology. It breaks the traditional conveying means to transfer goods in high altitude orbit.

- Smart management of conveyor line.

- Air transportation takes no floor space in the production area.

- Smart shuttle robot can travel to any locations of the production line to achieve flexible transfer.

- Intelligent managed conveyor system allows the robot to automatically transfer from temporary storage zone to production line.

- Overhead transportation occupies no floor space of the production zone.