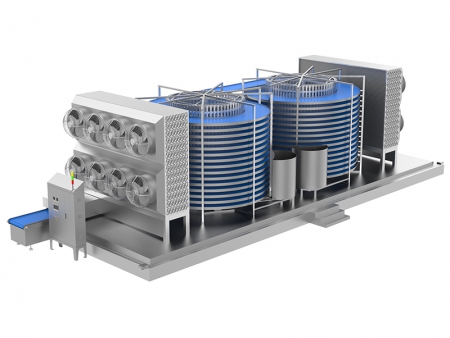

Double Spiral Quick Freezer

Double Spiral Quick Freezer

The double spiral quick freezer is a highly efficient and area-saving piece of equipment specifically designed for quick-freezing. Its two spiral design helps products, such as bread, cakes, meat, poultry, fish, ice cream, and dairy products, move on a mesh belt spirally, freezing them quickly and efficiently. This freezer is also useful in cooling and bread fermentation applications.

Design philosophy of cost-effectiveness and usability

This quick freezer has been designed using the latest European technology, combining mechanical and electronic protection to ensure safe and trouble-free operation. The process is user friendly and allows for flexibility when it comes to feed direction and integration of other machinery into a production line. This enables a seamless and efficient production cycle.

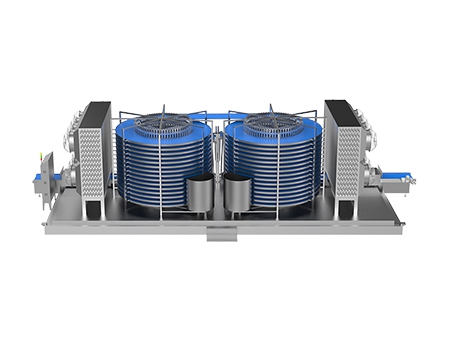

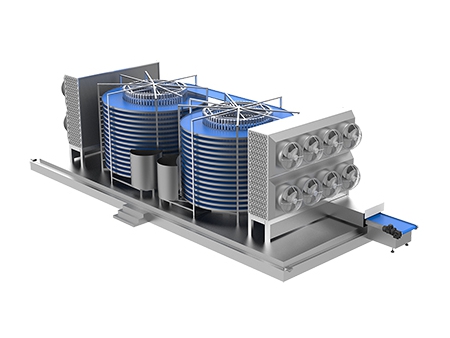

- Equipped with a double drum structure that maximizes the characteristics of the spiral quick freezer, significantly improving freezing efficiency

- The drums and conveyor belt are supported by UHMW polyethylene protective strips, which are both wear-resistant and durable, extending the lifespan of the stainless steel mesh belt. Its optimized airflow design ensures thermal insulation and prevents frosting on the evaporator, extending the defrosting intervals

- Features a high resistance to elongation and wear, enhancing the double spiral quick freezer’s service life and stability

- Fitted with a conveyor belt monitoring device to check the belt's working status continuously, preventing unnecessary losses due to belt malfunctions

| Cage Diameter | 1620-5800mm |

| Layers of Conveyor Belt | Level 6-40 |

| Belt Width | 520-1220mm |

| Belt Material | 304/POM |

| Infeed Belt Length | 500mm |

| Outfeed Belt Length | 500mm |

| Control Cabinet | Control panel with PLC touch screen control, 304 stainless steel enclosure |

| Refrigerant | Freon, ammonia, carbon dioxide |

| Evaporator | Aluminum/stainless steel tube, aluminum/aluminum-magnesium alloy fins |

| Defrosting Method | Water flushing/hot air defrosting |

| Freezer/Cooldown Time | Adjustable with variable frequency |

| Conveyor Belt Cleaning | CIP |

Depending on the relative position of the cage and the evaporator, the layout of the double spiral quick freezer can be classified into type A, B, and C.