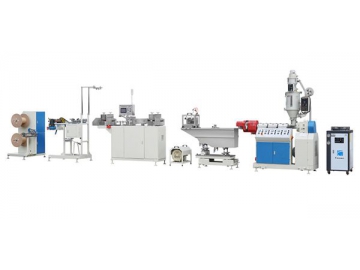

JL45C Colored Zipper Extruder

JL45C colored zipper extruder adopts co-extrusion technology, and is specially designed to make the multi-seal zipper profile in single color or double color. The extra extruder can co-extrude a coating layer of low-temperature sealable material on the zipper profiles, makes your zipper sealable to both PP and PE films. This extrusion line is versatile, you just need changing the die plates and you can produce various types of zipper profiles.

Parameters| Model | JL45C |

| Material | LDPE,PP |

| Production Speed | 10-50 |

| Zipper Width | 3-50mm |

| Thickness of zipper | 0.3-2.2mm |

| Diameter of screw | 45mm |

| Draw ratio of screw | 25:1 |

| Power of Main Motor | 5.5kw |

| Power of the auxiliary motor | 1.1kw |

| Power of dehydration and drying | 2kw |

| Zipper winding unit | 1.1kw |

| Heater Power | 6.8kw |

| Total Power | 22kw |

| Overall Dimension | 9350*1300*2200mm |

Production Line Composition

This extrusion line consists of chiller, one main extrusion part, two sets mini jl30 extruder for color strip, co-extrusion die head, automatic filter changer system, co-extrusion die plate, water tank (form the zipper at constant temperature), dehydrating system and air-drying unit with vacuum blower, zipper traction part, auto zipper-closing part and zipper rewinding unit.

The co-extrusion die plate of zipper can be designed according to customers’ sample or drawing.

- Die plates for different types of zipper

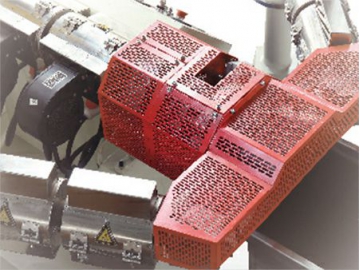

- Teeth Device on zipper Closing unit

- Teeth Device on zipper traction unit

- Based on the special demand of the material flow rate in zipper production, the charging barrel and the screw are made of high quality alloy steel with chrome plating, leading to strong resistance to abrasion, extreme heat, and deformation.

- The band heater for charging barrel comes with stainless steel surface and internal porcelain heater. An independent air blower for cooling is included, as well.

- Provided in one-piece structure, the filter screen for the die plate is easy for dismantling and cleaning.

- A stainless steel storage tank is equipped for the colored zipper extruder.

- The motor for the zipper extruding equipment adopts Panasonic frequency converters, domestically well known hard surface reducer, and the torque motor reeling machine. The impeccable configuration ensures the stable performance and high productivity of our high speed zipper extruder.

- An air plug is employed for power connector.

- To improve the zipper quality and the productivity, our colored zipper extruder uses frequency controller for the winding device.

- The live rollers for the front and back traction apparatus contain two turbine decelerating motors for group frequency control on the motor speed. (The front end of the live roller is connected by belt. In addition, the cycloidal pinwheel speed reducer is installed, as well).

- Coming with stainless steel plate workable, the colored zipper extruder has nice appearance and is convenient for operation.