LJ300 Al Flat Wire & Sector Line

Request a Quote

Continuous Extrusion Machine for Aluminum Wire, Strip, Busbar, Conductor, Aluminum Profile

This product has been discontinued and removed from our shelves.

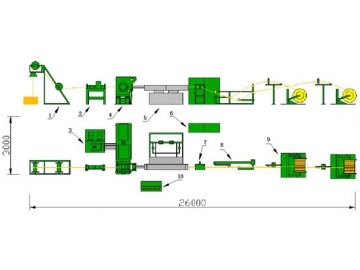

1. Payoff Unit 2. Straightening Unit 3. Continuous Extruder 4. Cooling and Drying System 5. Meter Counter 6. Guide Pulley 7. Take-up Machine 8. Hydraulic and Lubrication System 9. Electric Control Cabinet 10. Operation Console

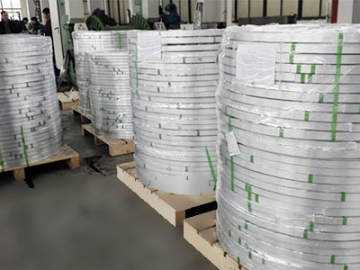

This range of continuous rotary extrusion line offers an ideal solution to product high quality aluminum flat wires which are often used to make power cables, transformers, welding machines, and more.

Aibang provides complete continuous extrusion line for making aluminum strip, aluminum bar, aluminum wire and aluminum profiles. Shown below are details of the aluminum continuous extrusion line.

Technical Specifications

| Main Unit: Continuous Extrusion Equipment | |

| Model | LJ300 |

| Nominal Diameter of Extrusion Wheel | 300mm |

| Rated Rotation Speed | 16.7RPM |

| Power of Main Motor | 110kW |

| Feedstock: Aluminum Rod | |

| Diameter | Φ9.5-12 mm |

| Diameter Tolerance | ±0.2mm |

| Yield Strength | <=90MPa |

| End Product: Flat Aluminum Wire | |

| Sectional Area Range | 5-150mm² (One mould can simultaneously extrude two or three products. 5 mm²) |

| Max. Width | 45mm |

| Standard | GB5585.1-85 |

| Flat Aluminum Wire Production Line | |

| Average Output | 100-200kg/h |

| Installed Capacity | 150V, 3 phase, 200KVA |

| Flash Amount | 1-2% |

Construction

| Aluminum Rod Payoff Machine | one pcs |

| Aluminum Rod Straightening Machine | two pcs |

| Scrubbing Machine | two pcs |

| Aluminum Rod Cutter | one pcs |

| Aluminum Continuous Extrusion Machine | one pcs |

| Cooling System | one set |

| Meter Counter | two pcs |

| Take-up Machine | two sets |

| Electrical Control System (with Touch Screen) | one set |

| Hydraulic and Lubricating System | one set |

Features

- The LJ300 continuous rotary extrusion line has the ability to produce flat aluminum wires in different shapes and specifications, because of its adoption of continuous extrusion machine with special mould cavity design.

- Due to continuous rotary extrusion technology, the extruded aluminum wire comes with smooth and burr-free surface, as well as uniform and densified structure.

- The continuous rotary extrusion equipment is designed with a special cooling system to extend the operation life of the extrusion die, thus cutting down the production and maintenance costs.

- According to customers' requirements, our continuous rotary extrusion line can be applied to continuously extrude aluminum products with unlimited length. Also, there won't be any joint on extruded products.

- With special extrusion die design, our range of aluminum extrusion machine supports extruding two or three aluminum wires synchronously. Thus, the production efficiency is largely improved.

Continuous Rotary Extrusion, Rotary Extrusion Machines, Aluminum Extrusion Equipment Manufacturer