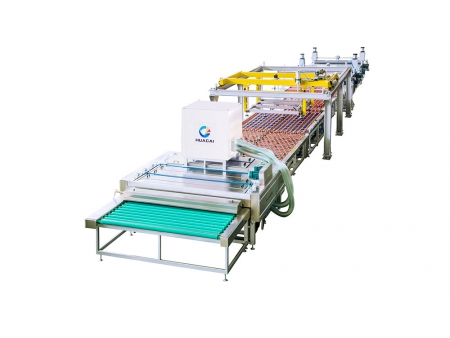

Flat Laminated Glass Line

Request a Quote

Technical Parameters

| Model | Max. Glass Size(mm) | Min. Glass length (mm) | Glass Thickness(mm) | Total Power of Quartz Tube Heater (KW) | Production Capacity(m²/8h) |

| 1600x6000 | 420 | 4-40 | 86 | 400 | |

| 2000x6000 | 420 | 4-80 | 114 | 520 | |

| 2500x6000 | 420 | 4-80 | 138 | 650 | |

| 2500x8000 | 420 | 4-80 | 156 | 800 | |

| 3000x6000 | 450 | 4-80 | 176.5 | 1300 | |

| 3300x15000 | 450 | 4-80 | 225 | 1600 |

Equipment introduction

The automatic glass laminating line consists of glass washing machine, automatic glass loading table, glass tilting table, automatic suction cup vacuum lifter, PVB laying machine, roller press and glass laminating autoclave, etc., achieving fully automatic production and higher production efficiency.

- The QX2500C-LOW-E glass washing machine features a horizontal structure and consists of loading, washing, drying and unloading section, air blower, electric control cabinet, etc.

- The auto positioning device features a horizontal design, made up of machine frame, positioning mechanism, transmission system, pneumatic system, electric control system, etc.

The machine body frame is welded by standard steel materials with a paint coat.

The main drive utilizes chain conveyor, VFD and digital display.The assembly table is equipped with a pneumatic lifting mechanism and universal wheels. The edges of the table are equipped with positioning wheels for glass positioning. - This suspended automatic suction cup vacuum lifter is used for transferring glasses, consisting of overhead crane (travelling track), pneumatic suction cups, vacuum system and electrical control system.

Vacuum pressure is controlled by the SMC high-precision vacuum generator.The lifting of suction cups is pneumatic, reliable and safe. PVB roll holder

Three rolls of PVB films with different specifications can be loaded. The unwinding and rewinding of membranes are manually operated. The changeover of film roller is hoisting replacement.GD2500 transition conveyor

The transition conveyor utilizes horizontal frame construction and consists of machine frame, transmission system and electric control system. The machine frame is welded by steel profiles and sprayed with paint.

The transition conveyor uses chain conveyor and the conveying speed is regulated by VFD and can be digitally displayed.- The glass heated roller press is comprised of the electrical cabinet and loading, pre-heating, pre-pressing (individual drive), 1st heating, 2nd heating, roll pressing (individual drive) and unloading section. After undergoing pre-heating, pre-pressing, heating and pressing, two or more layers of glasses and a PVB interlayer are bonded together to form an initial laminated glass. Imported high-temperature-resistant rubber rollers are able to put uniform pressure on the passing through laminated glass to remove air bubbles and ensure perfect adhesion effects between the constituent elements.

- Glass laminating autoclave is an essential equipment in a glass laminating line. It firmly combines layers of glasses and plastic interlayers through heating, pressurization and cooling process. The glass laminating autoclave consists of heating, cooling and heat preservation parts. The glass laminating autoclave also includes an intelligent control system.