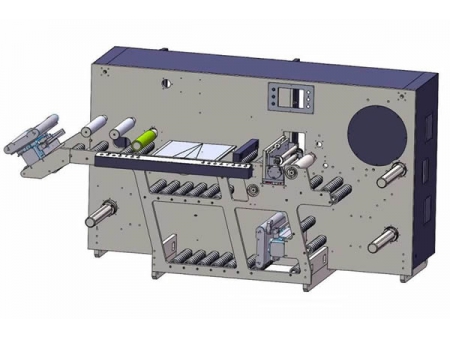

Automatic Label Inspection Machine, ZJP-330

ZJP-330 automatic inspection machine is a high-end automatic label inspection solution which was created by ZONTEN and BST company. It's specially designed for label quality inspection of large label printing factories.

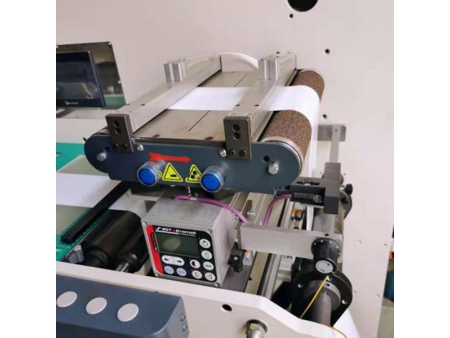

The rewinding and unwinding of the automatic inspection machine is driven by Mitsubishi servo motor, French SICK color tracking system, and German BST web guiding system. These imported devices guarantees the stable operation of the label inspection equipment.

The TubeScan inspection system from BST Company can monitor the printing quality problems such as missing labels, dirty labels, and unstable color registration. The automatic label inspection machine can be added with a slitting function, which can detect the label slitting in one step, and also has forward/reverse rotation function.

| Model | ZJP-330 |

| Max. inspection width | 30-240 mm, customizable |

| Max. inspection speed | 0.08mm (width) × 0.14 mm (Length) |

| Image resolution | Customizable |

| Mini. defect size (as a point) | 0.15mm²(Contrast≧20) |

| Mini. defect size (W x L) | 0.15mm×5mm(Contrast≧20) |

| Mini. color accuracy | △E≧3 |

| Mini. registration precision | ±0.2 mm |

| Material thickness | 0.08-0.4 mm |

| Max. rewind diameter | 800 mm / 650 mm |

| Inner core diameter | 76-150 mm |

| Module (optional) | Supervision Code, 2D Code, etc. |

- BST web guiding system

- Automatic paper feeding

- Servo driver and PLC control from a Japanese brand

- 6 inch air shaft

- Inspecting system is optional upon request