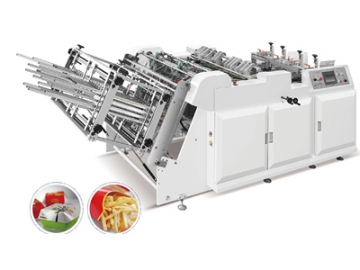

Double Lane Tray Former, ZX-1600

Request a Quote

Double lane tray former is designed with compression module to directly erect cardboard food boxes and trays which are suitable for both liquid and solid foods, it significantly increases efficiency compared to conventional box folding gluing machine which requires two steps to conduct.

This tray forming machine is CE compliant, and features stable transmission, high production efficiency, small footprint. Through rapid changeover, various types of cardboard takeaway containers, french fry boxes, hamburger boxes, hot dog trays and other similar cardboard packaging products can be efficiently produced by one machine.

Examples of Cardboard Food Containers

Technical Specifications

| Model | ZX-1600 | |

| Machine speed | 100-320pcs/min | |

| Material | 200-620gsm Cardboard thickness:1.6mm | |

| Container size | Length | L100-450mm |

| Degree:5°-45° | ||

| Width | B100-600mm | |

| Height | H 15-200mm | |

| Power | 6kW | |

| Air supply requirements | 0.5Mpa, 0.4m³/min | |

| Power supply | 380V 50Hz | |

| Machine dimensions | 3600×1850×1700mm | |

| Machine weight | 2800kg | |

Features

- Servo controlled forming module provides higher precision in comparison with mechanical cam control;

- Fully servo system is adopted to replace cam system;

- Easy changeover can be performed in shorter time, enabling various types of products to be formed in an efficient manner;

- The machine is completely controlled by PLC system, able to build complex cardboard boxes and trays;

- Automatic collecting, storing and counting;

- User-friendly control panel, safe and easy to operate;

- Operating parameters are storable by PLC, greatly saving time;