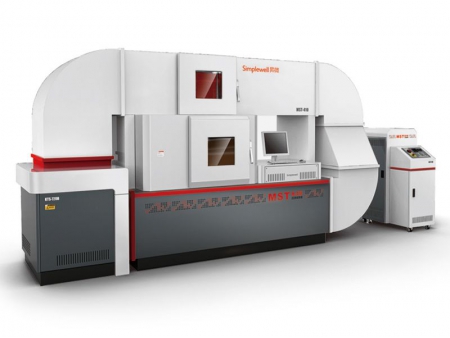

High Temperature Fire Alarm Detection System

Request a Quote

The fire detection and alarm system passed industrial quality test for temperature-sensing alarm and complies with EN54-2 GB47816-2005 U1521 standard.

Technical Parameters of Fire Detection and Alarm System

| Temperature range | 10-180℃ |

| Temperature increase speed | 0.1-30℃min, adjustable |

| Temperature deviation | ±2℃ |

| Air speed | 0.5-1.0ms, adjustable |

| Air flow | Stable |

| Test accuracy of temperature | ±0.2℃ |

| Test accuracy of air speed | 0.15m/s |

| Software testing | Yes |

Simplewell controller Mitsubishi PLC Temperature and humidity adjustment range

1. Rotary dehumidifier/ polymeric membrane, with a lowest temperature/ humidity content of 5℃/5 %RH.

2. Built-in tempered glass door, easy to move

3. Water purification system, with automatic replenishment function

4. Recorder, save and print testing data

5. Ultrasonic humidifier/ high-pressure spray humidifier, providing continuous high humidity under extreme temperature

6. Dry air blow system, anti-condensation

7. Remote monitoring function, cellphone and computer supportive

Cooling Equipment

TECUMSEH fully hermetic compressor BOCK inverter compressor BITZER semi-hermetic compressor