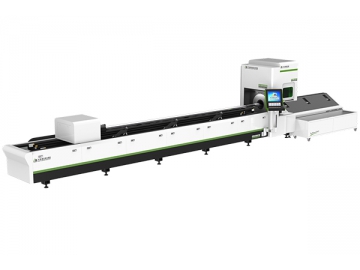

Fiber Laser Tube Cutter PCM60022-A

Technical parameters:

| Model | PCM60022-A |

| Tube diameter(mm) | φ20-φ220 |

| Max. tube length(mm) | 6000 |

| Overall dimension(mm) | 12000×2200×2300 |

| Laser power (W) | 500-3000 |

| Max. working speed (m/min) | 60 |

| Positioning accuracy (mm) | ±0.03/1000 |

| Power (Kw) | 12 |

| Weight (Kg) | 6500 |

| Power supply | Three phase 380V/50Hz/60Hz |

| Working environment | Temp.: 0~ 45°C, Humidity≤80%, no condense water |

Samples:

- Stainless steel tube cutting

- Stainless steel cutting

- Titanium tube cutting

- Carbon steel tube cutting

Features:

1.Pneumatic auto-centering chuck realizes symmetric and independent double clamping which doesn’t require manual intervention or adjustment. The chuck features simple but sturdy structure, good sealing and dynamic performance, able to clamp a variety of materials like square tube, round tube, flat tube, oval tube, triangular tube and profile steel.

2.Intensive chassis is processed by high-strength square tube welding technology to achieve high precision and stability and effectively eliminate the shock in high-speed cutting.

3.Imported large gantry milling machine is processed through tempering treatment and vibration aging to eliminate stress and its geometric accuracy is within 0.03mm.

4.Germany IPG laser generator has high wall-plug efficiency of over 30%, greatly saving power and achieving the highest production efficiency.

5.Auto-focus laser cutting head realizes perforation time reduced by 80% compared to regular laser cutting head. Integration with detailed cutting parameters database eases operations.

6.Cutting head conducts leapfrog and parabolic motion between the cutting contours. Automatic frog leaping is performed while contours switching to greatly enhance cutting efficiency.

7.The cutting head can directly locate the center of the pipe which enhances cutting efficiency performance;

8.Professional nesting and cutting software are highly compatible with the cutting system, which feature functions of power control, automatic edge searching, sharp corner smoothing, high-speed piercing and fast array scanning cutting.