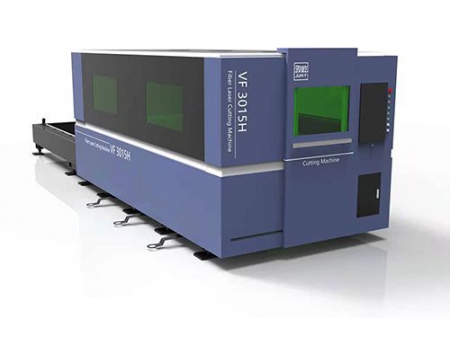

Fiber Laser Cutting Machine, VF3015H Fully Enclosed Fiber Laser Cutter with Shuttle Table

- Working area (L*W): 3050*1540mm*2

- Laser power: 3000W/4000W/6000W

- Positioning accuracy: ±0.03 mm/m

- Repositioning accuracy: ±0.02 mm/m

- Max. speed: 150000 mm/min

- Dimensions (L*W*H): 7943*2300*2257 mm

- Weight: 6.5 ton

This edition of fiber laser cutting machine was developed in response to the global customer needs of high power fiber laser system for the metal cutting industry. The automatic shuttle table system allows fast exchange between two platforms, enabling the metal sheets to be conveniently loaded and unloaded. The integral machine body of this fiber laser cutter allows for easy transportation with one 40HQ shipping container, this helps metal fabricators obtain lower shipping cost. Heavy duty machine bed is configured to permit a high power fiber laser source of up to 6kW.

- Fully enclosed with negative pressure, three fans are installed inside to ensure that dusts and wastes are ejected from vents at the bottom of the fiber laser cutting machine;

- This fiber laser cutting machine can be easily loaded into shipping containers for export without dissembling protective cover thanks to its compact structure. It can be directly put into use after delivery;

- Table exchange switch and emergency stop button are located at the middle of the laser cutting machine, enabling loading and unloading to be easily accomplished;

- For easy maintenance of parts and Y-axis guide rail within the enclosure, doors are installed on either side of the fiber laser cutting machine;

- Safety measures are available in line with international standards, as evidenced by the equipping with four light curtains that emit infrared lights;

- Multiple dust collectors are installed to function in step with the negative pressure system, enabling the dust to be easily removed;

- The machine body will remain stable after ten years of use and will not deform under full acceleration of 1.2G;

VF3015H fully enclosed fiber laser cutting machine with exchange table has been skillfully manufactured to meet our rigid standards of metal sheet processing machineries. It can guarantee stable operation and accurate cutting of a number of metal materials including stainless steel, carbon steel, aluminum, brass and more. This fiber laser cutting machine can be widely used in a variety of industries like automotive, aerospace, electrical parts, mechanical fabrication, kitchen appliance, metal doors and windows, etc.

The full cover fiber laser cutting machine adopts CE marked safety glass as its laser protective glass observation window, through which the entire laser cutting process can be monitored and observed, significantly improving the operation safety. Smoke and dust treatment system absorbs and filters smokes and small particles generated during cutting, realizing virtually green and environmentally friendly production process.

Independently located control panel ensures all electrical parts are arranged in an orderly manner. The electrical panel air conditioning is offered to guarantee constant-temperature dust-free operation and prolong the service life of electrical elements.

High performance Japan servo motor provides maximum speed of 4000r/min. Coupled with lightweight aviation aluminum beam, the servo motor can increase acceleration to 1.2G while maintaining a high stability of machine operation.

The machine bed of fiber laser cutter is strengthened using reinforcing ribs to enhance tensile strength without distortion under extremely high or low temperature working environment, thus ensuring a stable metalworking process.

Intelligent operating system delivers high visibility allowing the operator to real-time surveillance of processing parameters such as power, air pressure and duty cycle, it can also present parameters for customer reference based on sheet metal thickness and the effect of laser cutting.

The automatic shuttle table system allows fast exchange between two platforms within 15-20 seconds, this enables the metal sheets to be conveniently loaded and unloaded, while lowering labor cost and increasing working efficiency. Optional material storage tower can be placed on either side of the fiber laser cutting machine to make the process of workpiece loading and unloading simpler and easier.

- We have over 10 years of experience in the field of laser equipment, capable of providing you with reliable laser machines with appropriate solutions tailored to your individual applications.

- We have a team of more than 100 professionals, and our customer service department will provide you with technical support as well as complete pre-sales, sales and after-sales service.

- Our products are approved by over 3000 customers around the globe, the reliable performance of our equipment and excellent service are highly appreciated by our customers worldwide.