202A Egg Washer (10,000 EGGS/HOUR)

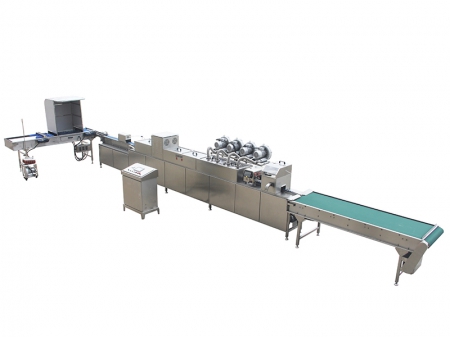

Made of strong stainless steel for great durability and hygiene. The Zenyer 202A is comprised of 202A main machine, 605A accumulator, 602 vacuum egg lifter, and optional manual packing lane.

Eggs are vacuum lifted and loaded onto 605A accumulator using the 602 vacuum egg lifter. 6 rows LED lights are added under the accumulator and workers can pick out any leaking, dirty or cracking eggs through the LED lights. The LED candling booth equips with cover and mirror as well to reinforce the candling result. The accumulator will direct 6 lines of eggs into 1 line and transport them to the single conveyor egg washer.

It can connect with the ZENYER / egg grader to build the ZENYER / egg processing linewith capacity of 10,000 eggs/hour.

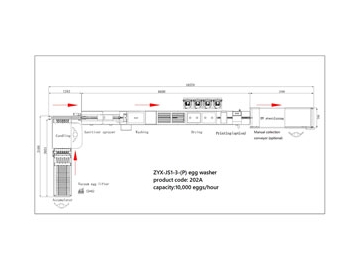

| Product name | Egg cleaning machine |

| Product code | 202A |

| Model | ZYX-JS1-3 |

| Capacity | 10,000 eggs/hour |

| Material | Stainless steel |

| Power* | 10.8KW |

| Voltage* | 380V, 50HZ, three phase |

| Dimension(L×W×H) | 7.8*3.9*2.0 M |

| Net weight* | 800KG |

| Gross weight* | 1050KG |

| Function | Vacuum lifter and accumulator loading, candling, sanitizer spraying, brushing, drying, optional egg printer and manual packing lane with UV |

Notes

* Power, net weight and gross weight are calculated according to the floor plan above.

* The voltage and frequency may be different due to different countries. For more details of electrical data sheet, please check with the ZENYER representatives.

- Vacuum egg lifter & Accumulator

- Sanitizer sprayer

- Washing

- Drying

- Printing (optional)

- Manual packing with UV(optional)

Eggs are vacuum lifted and loaded onto the using the ZENYER . 6 rows LED lights are added under the accumulator and workers can pick out any leaking, dirty or cracked eggs through the LED lights. The LED candling booth equips with a cover and mirror as well to reinforce the candling result. ZENYER 605A accumulator will direct 6 lines of eggs into 1 line and transport them to the single conveyor egg washer.

Sanitizer sprayer sprays chemical liquid (such as sanitizer, detergent depending on the local government policy) on eggs automatically before washing.

- Before washing

- After washing

Eggs are well cleaned by brushes with warm water spraying (the machine doesn’t come with a water heater, customer provides it). Brush modules are flexible, and adjustments can be made on brush distance, position and speed.

Eggs are perfectly dried by drying brush and strong air generated by drying fans.

ZENYER could be attached at the end of egg cleanser, you can print your farm name, logo, date, best before date, etc. on eggs.

Washed eggs will roll onto the conveyor (motor drive) and can be placed into trays manually. It could instead be attached to the ZENYER / egg grader to create the / egg processing line instead.