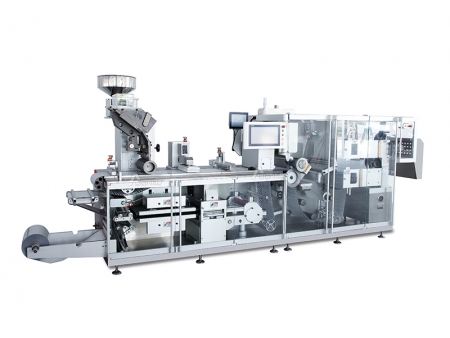

Roller Type High Speed Blister Packing Machine

Request a Quote

DPH Series

Automatic blister packaging machine is constructed for the ALU/PVC and ALU/ALU packaging of a variety of pharmaceutical and foodstuff products, such as tablets, capsules, pellets, candies, as well as other industrial objects.

Technical Specifications

| Terms | ||

| Operation speed | ALU/PVC 60-200Times/Min | |

| ALU/ALU 80Times/Min | ||

| Travel range | 100-280mm | |

| Max. forming area | 320×280mm | 260*280 |

| Max. forming depth | ALU/ALU 9mm | |

| ALU/PVC 12mm | ||

| Main motor power | 3KW | 2.2KW |

| Power supply | 3P 5Line 380V 50HZ 18.9KW | 3P 5Line 380V 50HZ 15.5KW |

| Air pressure | 0.1-0.15MPa | |

| Air consumption | ≥0.5 m3/min | |

| Water consumption | 1.5P with 60L/h | |

| Dimension | 4860X1480X1750mm | 4860X1400X1750mm |

| Weight | 4500Kg | 4000 |

Features

- The heating plate at forming station is opened and closed automatically, and the machine will delay to start until the forming material reaches set temperature, thus reducing the waste of material;

- Pneumatic cushion heating mechanism, the upper sealing molds (web plate) is driven by a pneumatic cylinder to rise up when power off, avoiding the blister package deformation caused by heat radiation during the machine stop;

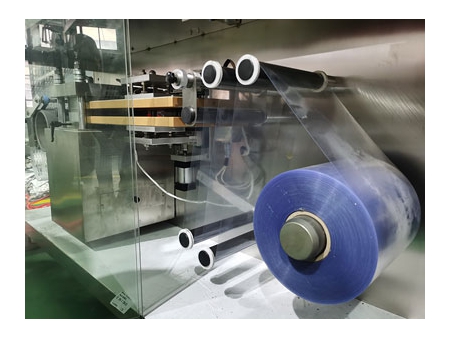

- Roll heat sealing mechanism, the linear contact between the heat seal roll and anilox roll achieves higher sealing pressure due to smaller sealing area, providing an excellent sealing efficiency;

- Automatic alarm system for broken or run out of Alu foil and PVC film, with emergency stop safety device, enhancing the safety of operator during the operation;

- Servo stepper motor is adopted to ensure precise synchronization in running;

- Machine oiling is carried out every 10 minutes (can be set accordantly) by oil pump to lubricate and cool the machine, guaranteeing the smooth operation while prolonging the service life;

- Protection functions:

1) Machine automatically stops when there is a shortage of Alu foil and PVC film;

2) Alarm will be automatically activated when there is a shortage of packaging products;

3) Machine automatically stops and triggers alarm when air pressure is insufficient;

4) Heating system will be automatically stopped when the any temperature exceeds the limit, protecting the electrical system from being damaged;