Ice Cold Storage

Cold Storage Capacity: ≥500m³

Normally, the ice made by the ice machine needs to be stored in time to avoid melting. The ice cold storage design varies depending on the user's applications or ice types. Commonly there are V-type ice storage, low-temperature ice storage, rake type ice storage, etc.

The ice storage is suitable for storing cube ice and tube ice, and the ice storage capacity usually ranges between 800kg and 3000kg. This cold storage features a V-shaped structure, through which the ice produced by ice-making machine are gathered and dropped onto the screw conveyor of ice storage, and then the ice will be automatically out-fed from the ice storage through the screw conveyor to realize the automatic ice outfeed and quantitative packaging.

- All stainless steel 304 construction, food-grade standards;

- No compressor set, the cold storage is at room temperature;

- The screw conveyor uses motor to achieve automatic harvesting of ice;

- Pedal switch enables the machine to be operated or stopped at any time;

- Configured with quantitative weighing unit, greatly improving packaging efficiency;

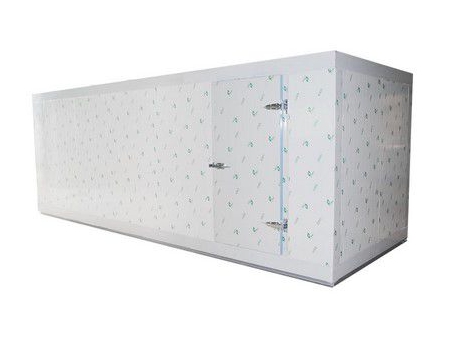

For users who sell ice or have large tonnage ice machines, it is necessary to configure with low temperature ice storage. Storing ice produced by ice machine in the cold storage can increase economic benefits. The storage temperature of the low temperature ice storage is below -10°C.

This cold storage adopts insulation boards for every door, wall and roofing. There is an additional refrigeration unit used to keep the indoor temperature of the ice storage at -10°C. The produced ice can be automatically conveyed out of the ice storage by means of automated conveying system. The rake-type automatic ice storage is generally a medium-sized ice storage with a capacity of 50-200 tons, it can be custom manufactured according to customers’ specific needs.