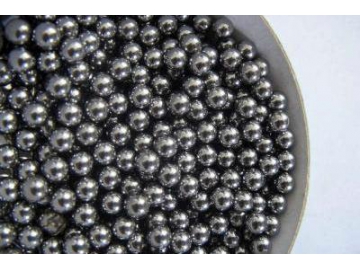

Chrome Steel Grinding Balls

Introduction

Chrome steel grinding ball can separate and grind materials, which is used in slurry of various kinds of bead mills and ball mills. The grain diameter of them is between 0.5mm to 150mm. The chrome content and ball size can be customized according to customers’ requirements.

Application

Chrome steel grinding ball can realize separation and grinding of dark printing ink, dye, oil paint, metallic pigment and other materials with high viscosity, high solid phase and high abrasion. It can be used as ball of bearing and seals. The steel grinding ball is suitable for cement building materials, metal mining, coal slurry pyroelectricity, chemical engineering, ceramic coating, light industry paper-making, magnetic materials and other industries.

| Processing methods | Type | Materials | Diameter range | Surface hardness | Volume hardness | Impact toughness | Crashed rate |

| Forging and hot rolled | Steel ball | B2 B3 BU | 0.5mm-150mm | 58-65HRC | 56-64HRC | 12J/cm² | <0.5% |

| Forging and hot rolled | Steel rod | Customized | Customized | 58-65HRC | 56-64HRC | 12J/cm² | <0.5% |

| Casting | Steel ball | Low chrome, medium chrome, high chrome, cast alloy ball | 8~150mm | 58-65HRC | 56-64HRC | 12J/cm2 | <0.5% |

- Chrome steel grinding ball has high hardness and wear resistance, which can improve production capacity, specific surface area of cement and the recovery rate of concentrate.

- Chrome steel grinding ball has better wear resistance compared with common carbon steel ball and it has long service life.

- High content chrome grinding ball for mine has good wear resistance and high grinding efficiency.