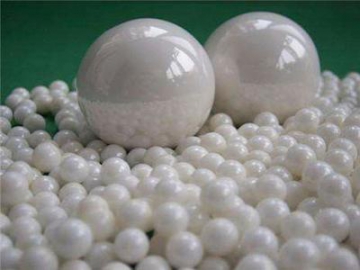

Zirconia Grinding Balls

Introduction

The zirconia grinding ball is made of nano-sized zirconia powder by iso-static pressing and high temperature sintering. Three is no pore and cavity in the ball and the inner of the ball forms homogeneous compact and stable quadrangle zirconia crystal structure(Ce-TZP), which has the same hardness, density and abrasion resistance like gemstone. We have different production types for different applications and the content of zirconia and the size of ball can be customized according to customer requirements.

Application

Zirconia grinding ball can be used as generic grinding medium for sand grinding mill, vertical agitator bead mill, horizontal rolling mill, vibratory ball mill, bead mill and ball mill. It is suitable for ceramic raw materials, pigments, electronic slurry and battery materials such as silk-screen printing ink with high solid phase, offset printing ink, digital printing, barium sulfate, zirconia, zirconia silicate, calcium bicarbonate, kaolin, electronic paste, zirconia oxide, rare earth and fine grinding of nanometer industries such as precious metal paste, metal paint, medicine, biochemistry and cosmetics industry.

Chemical composition

| Production type | weight percentage Wt% | |||||

| Al2 O3 | ZrO2 | Y2O3 | CeO2 | SiO2 | Others | |

| Zr-30 | 60% | 30% | 10% | |||

| Zr-40 | 50% | 40% | 10% | |||

| Zr-62 | 33% | 62% | 5% | |||

| Zr-64 | 33% | 64% | 3% | |||

| Zr-80 | 20% | 80% | ||||

| Zr-85 | 8% | 90% | 2% | 1% | ||

| Zr-90 | 10% | 90% | ||||

| Zr-93 | 93% | 7% | ||||

| Zr-95 | 95% | 5% | ||||

| Type | Density | Bulk weight | Moh's hardness | Vickers hardness | Compressive strength | Wear rate per ton | Fracture toughness | Elasticity modulus | Color | Package |

| Zr-30 | 3.8kg/dm3 | >2.1kg/L | 8 | 1200kg/mm2 | 800N(2mm) | 0.08kg/t | ||||

| Zr-62 | >4.0 kg/dm3 | >2.5kg/L | >7.0 | >900kg/mm2 | 1200N (2mm) | creamy-white | 25kg/barrel | |||

| Zr-64 | >4.0kg/dm3 | >2.5kg/L | >7.0 | >900kg/mm2 | 1200N(2mm) | creamy-white | 25kg/barrel | |||

| Zr-80 | 6.2 kg/dm3 | >3.8kg/L | 9 | >1200kg/mm2 | 15Mpa.m1/2 | 180Gpa | brown | |||

| Zr-85 | >5.2kg/dm3 | >3.2kg/L | 8.0 | >1050kg/mm2 | 1800N (2mm) | |||||

| Zr-90 | 5.3 kg/dm3 | 3.2kg/L | 8.0 | 1800N(2mm) | creamy-white | 25kg/barrel | ||||

| Zr-93 | 6.0 kg/dm3 | 3.6 kg/L | 9 | >1200kg/mm2 | 1900N(2mm) | White | 25kg/barrel | |||

| Zr-95 | >6.0 kg/dm3 | 3.6kg/L | 9 | >1200kg/mm2 | 10Mpa.m1/3 | 200Gpa | Milk white | 25kg/barrel |

| Type | Grain size(Φmm) |

| Zr-30 | 0.8-4.5 |

| Zr-40 | 2.0-12 |

| Zr-62 | 3.0-13.0 |

| Zr-64 | 0.4-6.0 |

| Zr-80 | 0.3-5.5 |

| Zr-85 | 0.6-4.0 |

| Zr-90 | 0.6-4.0 |

| Zr-93 | 0.4-3.2 |

| Zr-95 | 0.05-50 |

- Zirconia grinding ball has low wear rate, which is 1/100 of alumina balls.

- The smooth surface reduces the power consumption and wear on the contact parts of the equipment.

- Zirconia grinding ball suitable for dispersing and grinding materials which have oil by general purpose sand grinding mill.

- Long service life: 30 times than glass beads and 6-8 times than zirconium silicate beads.

- High grinding efficiency: 6-8 times than glass beads and 2-3 times than zirconium silicate beads.

- High grindable viscosity: viscosity of grinding can be 50000cps(centipoise).

- It has high specific gravity.

- High strength: no deformation and no broken.

- It is suitable for agitator bead mill of high-speed shearing.