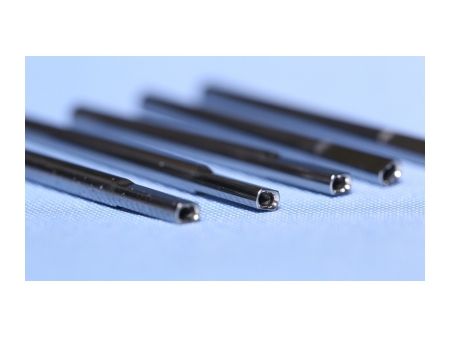

Tungsten Electrodes

HUAXINAG has been devoted to manufacturing tungsten electrodes for many years. These nonconsumable electrodes, mainly used in TIG welding, is generally composed of either pure tungsten or an alloy of tungsten and other rare earth elements such as thorium, lanthanum, cerium, zirconium and yttrium.

Now, our six commonly available tungsten welding electrodes to be talked below can meet various requirements for gas tungsten arc welding. Owing to different properties, these tungsten electrodes embody different functions and applications.

Thoriated Tungsten Electrodes

This type of TIG welding electrode is used mainly for AC welding and DC welding, either electrode negative or straight polarity, on carbon steel, stainless steel, nickel alloy, and titanium.

Due to extremely high current-carrying capacity, this 2 percent thoriated tungsten electrode can improve welding performance.

Lanthanated Tungsten Electrodes

The lanthanated tungsten electrode is great for welding carbon, stainless steel, nickel alloy and titanium.

Ceriated Tungsten Electrodes

The 2% ceriated tungsten electrode is mainly used for TIG welding, PLASMA welding, plasma cutting, plasma coating and plasma smelting as well as gas-discharge source

Zirconated Tungsten Electrodes

The zirconated tungsten welding electrode is the best non-radioactive electrode. It produces an extremely stable arc and has a high resistance to contamination. Also, it comes with high current-carrying capability.

Pure Tungsten Electrodes

The pure tungsten electrodes are typically less expensive than their alloyed counterparts. They provide great arc stability for AC welding, especially on aluminum and magnesium.

Yttriated Tungsten Electrodes

Owing to narrow arc beam, high compression strength and high welding penetration, the yttriated tungsten electrodes are mainly used in military and aviation industry.

If you want to have a comprehensive understanding about our products, please visit the page.