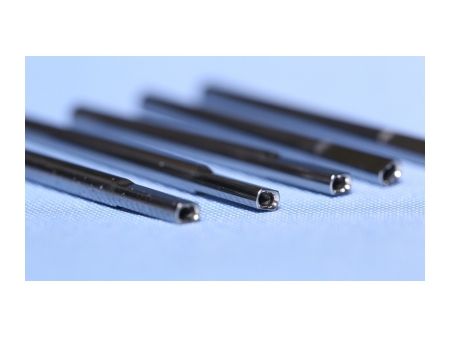

Thoriated Tungsten Electrodes

The thoriated tungsten electrodes are the most commonly used electrodes today and are preferred for their longevity, ease of use and superior welding properties. During long-term use, this type of industrial welding electrode can not be replaced by other oxide electrodes.

Features

1. HUAXIANG thoriated electrodes, widely used in AC welding on carbon steel, stainless steel, nickel alloy and titanium, are the first choice of high quality welding. They have the lowest work function, allowing them to carry a lot of current.

2. The thoriated tungsten electrodes boast superior properties over pure tungsten electrodes in many aspects. To be specific, the thorium oxide provides 20% more current-carrying capability than pure tungsten. Longer service life but less weld contamination can also be realized. In addition, this TIG welding rod allows easier arc start and eliminates arc wandering for greater stability.

3. Our WT10 and WT20 thoriated tungsten electrodes can all be used for DCEN. During welding, thorium is evenly dispersed throughout the electrode, which helps the tungsten maintain its sharpened edge. It is the ideal electrode shape for welding thin steel pipe. Generally, these tungsten welding electrodes are not used for DC welding.

Technical Parameters

| Models | Oxide Additive | Impurities Content % | Tungsten Content % | Color Standard | |

| Varieties | Content% | ||||

| ThO2 | 0.90-1.20 | <0.2 | Balance | Yellow | |

| ThO2 | 1.80-2.20 | <0.2 | Balance | Red | |

| ThO2 | 2.80-3.20 | <0.2 | Balance | Purple | |

| ThO2 | 3.80-4.20 | <0.2 | Balance | Orange | |

Product Standards

ISO 6848, ANSI/AWS, A5.12/A5.12M-98

Size

1. Diameter: 0.5-25mm

2. Length: 150mm, 175mm, 178mm (other lengths are available as per customer's requirements)

Electrode Diameter in Different Current Range

| Electrode Diameter | DC(A) | AC(A) | |||

| In | Mm | DCEN (-) | DCEP ( ) | Imbalanced Wave | Balanced Wave |

| 0.04" | 1.0 | 15-80 | 10-80 | 20-60 | |

| 1/16" | 1.6 | 60-150 | 10-18 | 50-120 | 40-100 |

| 0.079" | 2.0 | 100-200 | 12-20 | 70-160 | 60-130 |

| 3/32" | 2.4 | 150-250 | 15-25 | 80-200 | 80-150 |

| 1/8" | 3.2 | 220-350 | 20-35 | 150-270 | 120-200 |

| 5/32" | 4.0 | 350-500 | 35-50 | 220-350 | 170-260 |

| 3/16" | 4.8 | 420-650 | 45-65 | 240-420 | 220-340 |

| 1/4" | 6.4 | 600-900 | 65-100 | 360-560 | 250-450 |