Stamping Die for Body Side Panel

As an experienced designer of stamping dies, we can deliver reliable body side panels for nearly any car make or model. We use that expertise to help our clients produce body panels that are difficult for clients to find.

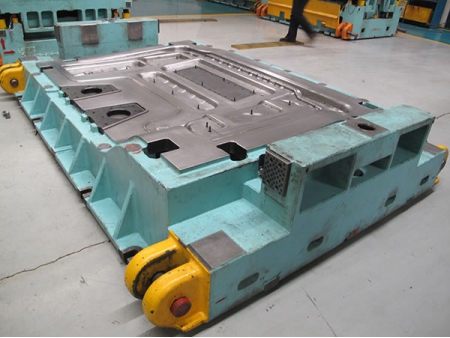

Featured on this page is the specialized die for body side panels. At Huanghe, we understand that each outer side body panel may be unique in terms of size, shape and material. Due to that, we ask that our customer provide technical information specific to the car model where the body panel is to be installed. Based on that information, our engineers can then design and manufacture the right stamping die for the car component.

As with other car parts, the production of the body side panel is carried out in several steps, each requiring different auto dies, including the blanking die, draw die, cam trim die/cam piercing die, cam action forming die, and the cam action piercing/forming die.

Blanking is the first step in body panel construction, and the finished part in this step is called a blank. In this stage, a blanking die is used to cut the outside contour of the body panel. The trickiest part of this process is making the best use of the raw material, in order to minimize waste.

The next process is drawing, which involves the most work among each of these steps. Drawing results directly affects the surface quality and the overall look of the finished car part.

The draw die is a unique unit that allows the blank to be drawn as a complete piece, rather than in various sections. This particular die is a showcase on our own technical tooling strength.

Large stamping dies are castings that are prone to deformation in daily use. Because of that, we put our semi-finished stamping dies through a quenching process to increase the hardness and tensile strength, and then follow up with a process known as vibratory stress relief to remove excess internal stress from quenching. The resulting work piece is then machined on the machine tool. To ensure the smoothness and a precise match at the parting surface of the two pieces of the stamping die, we use a 5-axis machining to ensure the quality.

It is not always possible to perform the flanging, trimming and piercing processes at an angle perpendicular to the working surface. Because of that, we provide side cam dies which allow for operation at nearly any angle, including 50, 75 or 90º angles.

This stage is essential for controlling the amount of deformation that occurs from heat treatment. Another key factor of the flanging, trimming and piercing process is effective scrap removal from the dies during operation.

The side ca dies use several wedge shaped cams to allow operations at different angles. The flanging mechanism includes a complicated cam driver, and this cam trim die can be integrated into an automated stamping line for fast production speeds.

When we produce side cam dies, we use sensors to assist in locating and removing defective parts. The die has pneumatic parts built in, simplifying the design and prolonging the service life. A cone shaped retainer is used to hold or secure the pressure pad on the dies shoe. Built to Volkswagen standards, the retainer ensures piercing and trimming accuracy. The result is a clean, burr free surface.

The forming die carries out bending operations on the panel. It is important to hold the panel in position, and analyze and control the amount of kickback on the panel where surface quality is critical.

This is the last step in the body panel stamping process. Be sure to accurately locate and clamp down the part where perforation is needed.

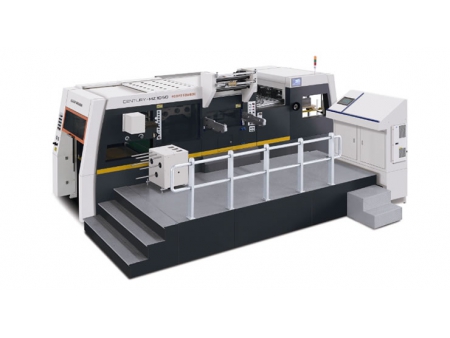

Showcase

Rear Part

Stamping Die for Front Part of Body Side Panel