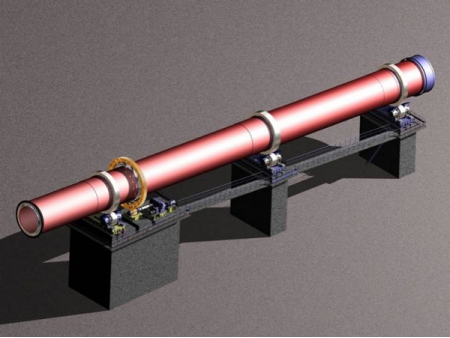

Rotary Kiln

A rotary kiln is a pyroprocessing device used for calcinating and sintering a broad range of materials like cement clinker, ferrites and dry powder. With a capacity ranging from 300 t/d to 10000 t/d, our rotary kiln is widely used in a variety of industries such as cement production, metallurgy and chemical processing. Our company has supplied rotary kilns to more than 500 cement production lines for many large projects in Pakistan, Vietnam, Middle east, Africa and SPCC, CCC, RCC, SCC, YCC projects in Saudi Arabia.

| Size (m) | Capacity (t/d) | Kiln Slop (%) | Number of Supports (pc) | Thruster Type | Rotational Speed | Main Drive | Aux Drive | |||

| Main Drive (r/m) | Aux Drive (r/m) | Motor Power (KW) | Reducer | Motor Power (KW) | Reducer | |||||

| Φ4x60 | 2500 | 4 | 3 | Hydraulic | 0.41-4.07 | 8.2 | 315 | 22.4 | 22 | 45 |

| Φ4.3x64 | 3500 | 4 | 3 | Hydraulic | 0.4-4.0 | 7.93 | 400 | 31.5 | 30 | 45 |

| Φ4.8x74 | 5000 | 4 | 3 | Hydraulic | 0.35-4 | 8.52 | 630 | 42.226 | 55 | 28 |

| Φ5.0x74 | 6000 | 4 | 3 | Hydraulic | 0.35-4 | 7.58 | 710 | 28 | 55 | 45 |

| Φ5.6x87 | 8000 | 4 | 3 | Hydraulic | Max4.23 | 8.7 | 800 | 23.901 | 90 | 35.795 |

| Φ6.0x95 | 10000 | 4 | 3 | Hydraulic | Max5 | 9.2 | 950X2 | 26.646 | 132 | 35.795 |

A rotary kiln mainly consists of a shell, main gear, gear cover, drive, support roller, hydraulic thrust, kiln head sealing device and kiln tail sealing device.

Kiln Shell

The bottom of the kiln shell is evenly distributed with several floating base plates for convenient installation and replacement.

Main Gear

Drive

When the main power cuts off, the auxiliary drive motor can still work to prevent the kiln shell from bending.

Support Roller

The support roller is a key part of rotary kiln which bears whole weight of kiln shell and fixes the kiln shell to ensure safe and stable operation

Hydraulic Thrust

The main function of hydraulic thrust is to ensure the axial reciprocating movement of riding ring and kiln shell at a certain speed, as well as to make riding ring and support roller stressed uniformly, resulting in prolonging the service life.

Sealing device

The rotary kiln is sealed with graphite to achieve good sealing performance. There are 2 ways to prevent the overstock of fine particle clinker, either by discharging the clinker into bottom ash hopper or into the grate cooler directly.