7-layer Air Bubble Film Extrusion Line

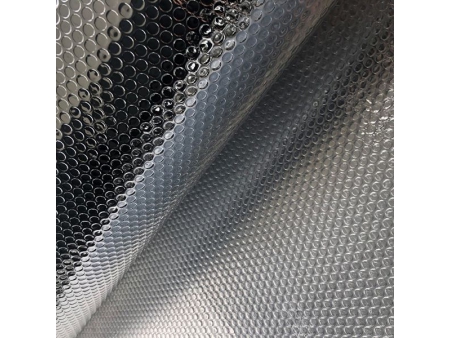

- Aluminum laminated air bubble film

- Aluminum laminated air bubble film

- EPE foam laminated air bubble film

As a specialist manufacturer of multi-layer bubble film lines, Pansatec has the ability to offer air bubble film extrusion line capable of manufacturing up to 7-layer bubble film roll that cosists of two layers of air bubbles laminated between three layers of flat polyethylene layers, and two PE coated layers on two sides. In addition to 7-layer air bubble film, this bubble film machine can also produce 2-layer / 3-layer air bubble films, and 3 to 5 layers laminated air bubble films with PE coated layer on one side or both sides.

- Wide range of PE coated layers, including PE coated aluminum foil, PE coated kraft paper, polyethylene film, PE coated antistatic film, PE coated nonwoven fabric, etc.;

- The design of double screw increases the productivity by 50%-80%, helping customers stay ahead in their competitive market;

- The thickness and color of each layer can be individually adjusted;

- Automatic cutting and rewinding, providing improved production efficiency;

- 24-hour continuous running, high reliability and easy to operate;

- SGS CE and ISO 9001 compliant;

- Stable production process, long service life;

Model: PT-L7-S3-W1200

Bubble film width (mm): 1200

Material: LDPE/LLDPE

Line speed (m/hr): 600-2100

Capacity (kg/hr): 85-140

Thickness (g/m2): 38- 300

Main screw diameter (mm): Φ65(x2)

Sub screw diameter (mm): Φ50

Heating power (kW): 82

Operation power (kW): 40

Installation power (kW): 122

Dimension (L×W×H) (m): 10×5.5×2.5

Weight (kg): 6500

Model: PT-L7-S3-W1600

Bubble film width (mm): 1600

Material: LDPE/LLDPE

Line speed (m/hr): 600-2100

Capacity (kg/hr): 100-170

Thickness (g/m2): 38-300

Main screw diameter (mm): Φ65(x2)

Sub screw diameter (mm): Φ50

Heating power (kW): 104

Operation power (kW): 51

Installation power (kW): 146

Dimension (L×W×H) (m): 10×6.5×2.5

Weight (kg): 7200

Model: PT-L7-S3-W2000

Bubble film width (mm): 2000

Material: LDPE/LLDPE

Line speed (m/hr): 600-2100

Capacity (kg/hr): 125-200

Thickness (g/m2): 40-300

Main screw diameter (mm): Φ75(x2)

Sub screw diameter (mm): Φ65

Heating power (kW): 136

Operation power (kW): 66

Installation power (kW): 201

Dimension (L×W×H) (m): 11×7.0×2.5

Weight (kg): 8000

Model: PT-L7-S3-W2600

Bubble film width (mm): 2600

Material: LDPE/LLDPE

Line speed (m/hr): 600-2100

Capacity (kg/hr): 145-220

Thickness (g/m2): 45-300

Main screw diameter (mm): Φ80(x2)

Sub screw diameter (mm): Φ75

Heating power (kW): 155

Operation power (kW): 75

Installation power (kW): 245

Dimension (L×W×H) (m): 12×8.0×2.5

Weight (kg): 9500

Model: PT-L7-S3-W3000

Bubble film width (mm): 3000

Material: LDPE/LLDPE

Line speed (m/hr): 600-2100

Capacity (kg/hr): 180-260

Thickness (g/m2): 45-300

Main screw diameter (mm): Φ90(x2)

Sub screw diameter (mm): Φ80

Heating power (kW): 180

Operation power (kW): 86

Installation power (kW): 298

Dimension (L×W×H) (m): 12×8.7×2.5

Weight (kg): 12000

| Model | PT-L7-S3-W1200 | PT-L7-S3-W1600 | PT-L7-S3-W2000 | PT-L7-S3-W2600 | PT-L7-S3-W3000 |

| Bubble film width (mm) | 1200 | 1600 | 2000 | 2600 | 3000 |

| Material | LDPE/LLDPE | LDPE/LLDPE | LDPE/LLDPE | LDPE/LLDPE | LDPE/LLDPE |

| Line speed (m/hr) | 600-2100 | 600-2100 | 600-2100 | 600-2100 | 600-2100 |

| Capacity (kg/hr) | 85-140 | 100-170 | 125-200 | 145-220 | 180-260 |

| Thickness (g/m2) | 38- 300 | 38-300 | 40-300 | 45-300 | 45-300 |

| Main screw diameter (mm) | Φ65(x2) | Φ65(x2) | Φ75(x2) | Φ80(x2) | Φ90(x2) |

| Sub screw diameter (mm) | Φ50 | Φ50 | Φ65 | Φ75 | Φ80 |

| Heating power (kW) | 82 | 104 | 136 | 155 | 180 |

| Operation power (kW) | 40 | 51 | 66 | 75 | 86 |

| Installation power (kW) | 122 | 146 | 201 | 245 | 298 |

| Dimension (L×W×H) (m) | 10×5.5×2.5 | 10×6.5×2.5 | 11×7.0×2.5 | 12×8.0×2.5 | 12×8.7×2.5 |

| Weight (kg) | 6500 | 7200 | 8000 | 9500 | 12000 |