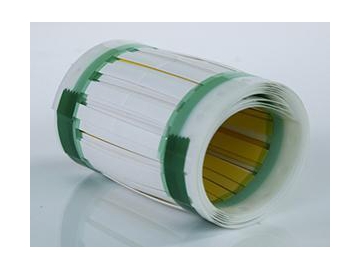

Heat Shrink Wire Marker, Flame Retardant Printable Heat Shrink Tubing

Model: CYG-MT(HX)

Material: Radiation-crosslinked modified polyolefin

Shrink ratio: 2:1, 3:1

Application

Flame retardant printable heat shrink tubing, with a product ID of CYG-MT (HX), features an excellent performance for UV resistance, and is designed to meet high performance identification requirements for cable manufacturers in closed or poorly ventilated environments. The print material of flame retardant printable heat shrink tubing meet the requirements of SAE-AS-81531MIL-STD-202 standards and can be used in an environmental temperature range of - 55 ℃ to 135 ℃. The flame retardant printable heat shrink tubing emits no smoke, is non-toxic, and has an excellent organic solvent and flame resistance.

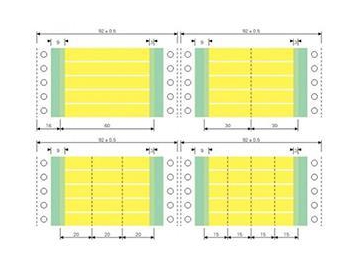

CYG-MT (Shrink ratio: 2:1)

| Size | As supplied (mm) | After recovery (mm) | Continuous packing (m/plate) | Cassette packing number per roll | ||

| Inside diameter (D) | Wall thickness (T) | Inside diameter (d) | Wall thickness (t) | |||

| Ф2.4 | ≥2.4 | 0.27±0.05 | ≤1.2 | 0.51±0.08 | 30 | 2000 |

| Ф3.2 | ≥3.2 | 0.27±0.05 | ≤1.6 | 0.51±0.08 | 30 | 2000 |

| Ф4.8 | ≥4.8 | 0.27±0.05 | ≤2.4 | 0.51±0.08 | 30 | 2000 |

| Ф6.4 | ≥6.4 | 0.32±0.06 | ≤3.2 | 0.64±0.08 | 30 | 1500 |

| Ф9.5 | ≥9.5 | 0.32±0.06 | ≤4.8 | 0.64±0.08 | 30 | 1500 |

| Ф12.7 | ≥12.7 | 0.32±0.06 | ≤6.4 | 0.64±0.08 | 30 | 500 |

| Ф19.1 | ≥19.1 | 0.36±0.06 | ≤9.5 | 0.76±0.08 | 30 | 500 |

| Ф25.4 | ≥25.4 | 0.45±0.08 | ≤12.7 | 0.89±0.08 | 30 | 250 |

| Ф38.1 | ≥38.1 | 0.50±0.08 | ≤19.1 | 1.02±0.15 | 30 | 250 |

| Ф50.8 | ≥50.8 | 0.58±0.08 | ≤25.4 | 1.14±0.18 | 30 | 250 |

Remarks: other sizes and color are available upon request.

CYG-MT (Shrink ratio: 3:1)| Size | As supplied (mm) | After recovery (mm) | Continuous packing (m/plate) | Cassette packing number per roll | ||

| Ф2.4 | ≥2.4 | 0.22±0.05 | ≤0.8 | 0.53±0.08 | 30 | 2000 |

| Ф3.2 | ≥3.2 | 0.22±0.05 | ≤1.1 | 0.58±0.08 | 30 | 2000 |

| Ф4.8 | ≥4.8 | 0.22±0.05 | ≤1.6 | 0.58±0.08 | 30 | 2000 |

| Ф6.4 | ≥6.4 | 0.22±0.05 | ≤2.1 | 0.58±0.08 | 30 | 1500 |

| Ф9.5 | ≥9.5 | 0.20±0.05 | ≤3.2 | 0.61±0.08 | 30 | 1500 |

| Ф12.7 | ≥12.7 | 0.20±0.05 | ≤4.2 | 0.61±0.08 | 30 | 500 |

| Ф19.1 | ≥19.1 | 0.20±0.05 | ≤6.4 | 0.61±0.08 | 30 | 500 |

| Ф25.4 | ≥25.4 | 0.20±0.05 | ≤8.5 | 0.64±0.08 | 30 | 250 |

| Ф38.1 | ≥38.1 | 0.30±0.06 | ≤12.7 | 1.00±0.15 | 30 | 250 |

| Ф50.8 | ≥50.8 | 0.30±0.06 | ≤17.0 | 1.00±0.18 | 30 | 250 |

Remarks: other sizes and colors are available upon request.

Performance index| Item | Test methods | Specifications |

| Tensile Strength | SAE-AMS-DTL-23053 | ≥10.3MPa |

| Ultimate Elongation | SAE-AMS-DTL-23053 | ≥200% |

| Flexibility | SAE-AMS-DTL-23053.4.6.7 | -55℃±1℃, 4h, No cracking |

| Heat Shock | SAE-AMS-DTL-23053.4.6.8 | 250℃±3℃, 4h, No cracking, dripping, flowing |

| Aging Performance | SAE-AMS-DTL-23053.4.6.9 | 175℃±2℃, 168h, No visual damage |

| Tensile Strength After Aging | SAE-AMS-DTL-23053.4.6.13 and ASTM D638 | ≥6.9MPa,23℃±2℃ |

| Ultimate Elongation After Aging | SAE-AMS-DTL-23053.4.6.13 and ASTM D638 | ≥100%,23℃±2℃ |

| Color Stability | SAE-AMS-DTL-23053.4.6.15 | 175℃±2℃, 24h, Pass |

| Dielectric Strength | SAE-AMS-DTL-23053.4.6.13 and ASTM D2671 | ≥19.7kV/mm,23℃±2℃ |

| Volume Resistance | SAE-AMS-DTL-23053.4.6.13 and ASTM D876 | ≥1.0x1014Ω· cm,500V (DC),60s |

| Flammability | SAE-AMS-DTL-23053.4.6.14 and ASTM D2671 UL224 | Self-extinguishing within 60s, ≤25% damaged area of print information, no dripping or large area falling |

| Fluid Resistance | AE-AMS-DTL-23053.4.6.11 | No visual damage |

| Print Persistence | SAE-AS-81531.4.6.2 | 50 rubber erasure , identification |

| Print Solvent Resistance | MIL-STD-202G Method 215K | 10 rubber erasure , identification |

- Print material meets UL224 and RoHS standards.

- Print performance meet SAE-AMS-DTL-23053/5 requirements.

- Various product packaging methods to meet different customer requirements.

- Can be printed with a standard dot matrix printer or heat transfer printer.

- Readable with double-side printed.

- Product color can be customized, though standard colors are white and yellow

- Great anti-pollution ability and print persistence.