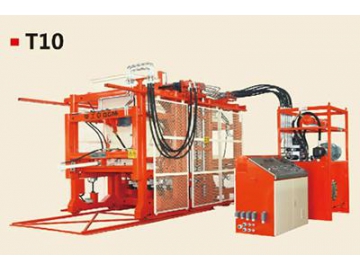

ZN1200S Automatic Block Making Machine

Application

The ZN1200S automatic block making machine can produce various building materials, including exposed wall blocks, interior wall block, tracery wall block, floorslab block, reinforcing dam block, inter-locking block, curbstone and other blocks. Eachmould can produce 12 blocks of 400×200×80mm. This machine is complete with a surface material feeding device and can produce color paver bricks.

This block making machine adopts sand, stone, stone power and cement. And large quantities of coal ash, cinder, gangue, ceramsite, perlite, construction waste, domestic waste and other industrial wastes can be added.

| Molding cycle | 15-25S |

| Exciting force | 120KN |

| Motor frequency | 50HZ |

| Total motor power | 68KW |

| Total weight | 16T |

| Dimensions | 9100×4800×3170 mm |

| Specifications | Molding cycle(seconds/mold) | Molding block number(number per mould) | Finished product drawings |

| 240×115×53 | 15-20s | 70 | |

| 240×115×90 | 15-20s | 35 | |

| 390×190×190 | 15-20s | 12 | |

| 200×100×60 | 20-25s | 48 | |

| 225×112.5×60 | 20-25s | 35 | |

| 250×250×60 | 20-25s | 15 | |

| 400×200×80 | 20-25s | 12 |

1. The Zenith block making machine adopts frequency conversion control to reduce the starting current of the motor. This achieves the synchronous operating of vibration assembly and solves the inertia problem motor when stopping, saving power by 20-30%.

2. With the adoption of Germany Siemens PLC and Siemens touch screen control, the operation is easy, the overall fault is low and the operating data can be saved permanently.

3. The hydraulic system is controlled by proportional valve to automatically adjust the flow during production, improving the operating stability and prolonging the service life of the cylinder.

4. The feeding car adopts 360° rotary feeding method with fast speed and uniform distribution, applicable to various raw materials and moulds.

5. After a carbonitriding treatment, the mould is resistant to wear and has a service life of over 50% longer than general moulds.

6. The machine is equipped with real-time fault diagnosis and alarming systems.

7. The vibration table is connected with the workbench and the hole spacing of the eccentric shaft is enlarged, reducing the loss of energy transfer, enlarging the effective vibration area and improving the vibration efficiency.

Block and brick models

1/2 long concrete block: QSZ45

Bond beam concrete block: QSZ28, QSZ27

Bullnose concrete block: B13, B19, B20, B9, B11, B12

Chimney block: QSZ26, QSZ27

Column block: QSZ24

Corner block: B3

Double block: C6

Half high block: QSZ37

Lightweight block: QSZ23, ZMG1002, ZMG1005, ZMG1007

Colored concrete block: QSZ33, QSZ34, QSZ35, QSZ36, QSZ40, QSZ41, QSZ42, QSZ43, ZMG1013, ZMG101