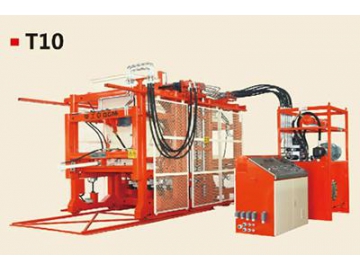

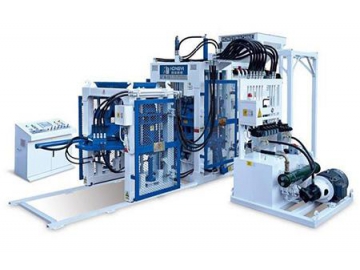

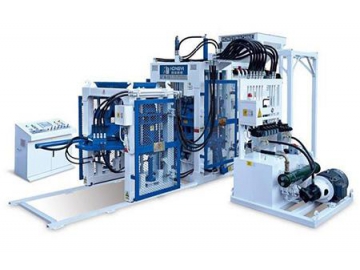

T15 Automatic Block Making Machine

Description

1). Vibration system

This T15 automatic block making machine employs frequency conversion vibration system with double vibration motors, namely 7.5 KW×4 Siemens motors for bottom vibration, and 5.5 KW×2 MVSI motors for top vibration. It is also equipped with the Siemens frequency converter.

2). Electronic system

Aside from Siemens S7 PLC, the product adopts touch screen and electrical components of Siemens and Turck.

3). Hydraulic system

The system is composed of integrated modular units from Germany and Italy, Rexroth pump and motors of ABB /Siemens.

4) The overall dimension (L x W x H):

with facemix device: 7,600 x 2,400 x 4,400mm

without facemix device: 4,600 x 2400 x4,400mm

Concrete products: 50-400mm in height

Pallets size: 1,400x1,100mm

Maximum production area: 1,300x1,050mm

| Main Technical Specifications | |

| Production per Mould: | 15 pcs/mould (Standard Block: 400x200x200mm) |

| 21 pcs/mould (Hollow Block: 400x150x200mm) | |

| 40 pcs/mould (Interlock: 225x112.5x60mm) | |

| 54 pcs/mould (Holland Brick: 200x100x60/80mm) | |

| Cycle Time: | 15-25s (Depending on Product Type) |

| Production per Shift (8 Working Hours): | Hollow Block (400x200x200mm): 24,000-28,800 pcs |

| Hollow Block (400x150x200mm): 33,600-40,320 pcs | |

| Interlock (225x112.5x60mm): 46,080-57,600 pcs | |

| Holland Brick (200x100x60/80mm): 62,200-77,760 pcs | |

| Vibration Frequency: | 5Hz-50Hz (300-3,000 rpm) |

| Vibrating Force: | 172 KN |

| Gross Weight: | about 22T |

| Raw Materials: | crushed stone, sand, cement, dust and coal fly ash, cinder, slag, gangue, gravel, perlite, and other industrial wastes. |

| Applied Products: | concrete blocks, solid/hollow/cellular masonry products, paving stones with or without face mix, garden and landscaping products, slabs, edgers, kerbstones, grass blocks, slope blocks, interlocking blocks, etc. |

| Applied Fields: | widely used in buildings, road pavings, squares, gardens, landscaping, city constructions, etc. |

| Note: All the production parameters are subject to change, without prior notice. | |

The capacity dates are theoretical and are dependent on machine settings, mix design, aggregates used and other environmental conditions.

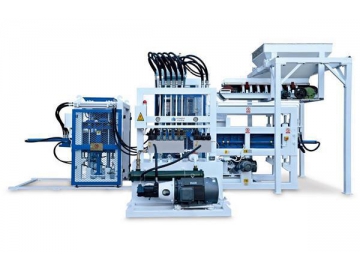

Production Line for Block Making:

A. Fully Automatic Production Line: (need 5 workers)

1. Silo

2. Screw

3. Aggregate weighing system

4. Face material weighing system

5. Mixers for main material and color material

6. Belt conveyor

7. Automatic block making machine

8. Conveyor for wet blocks

9. Elevator

10. Finger car

11. Lowerator

12. Conveyor for dry blocks

13. Stacker

14. Shipping pallet magazine

15. Tank conveyor

16. Pallet recycling device

17. Pallet turner

18. Control room

19. Curing room

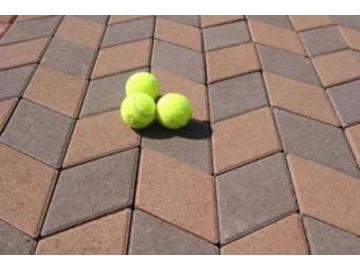

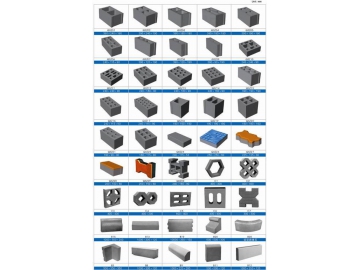

Block and Brick Models

Product Samples

This automatic concrete block making machine is capable of forming diversified blocks, such as the concrete block, solid or hollow block, paver block with or without pattern on the surface, slabs, curbstones, interlocking block, blocks used for garden and landscaping, etc. Some samples are presented as below.