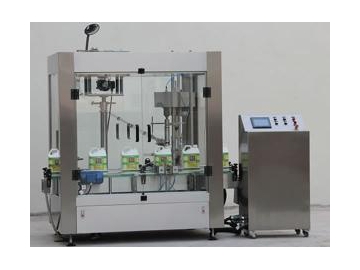

Automatic Screw Capping Machine(for 1-5L Flat Bottle/Drum), FX-1

This automatic screw capping machine for 1.5L flat bottles and drums can feed in bottles and caps, unscramble caps, cap bottles, and dispense finished bottles. We use international technology to automatically grasp and position caps precisely without damaging them. This efficient capping machine stops operation when it senses it is empty of caps. The bottle capping equipment also sense and removes damaged bottles.

- Power supply: 220V; 50Hz

- Power (kW): 1.5KW

- Air source: 0.6MPa clean and stable air

- Bottle size: height:80-280mm, width:40-80mm, length:80-120mm

- Cap diameter: Φ20-Φ70mm

- Cap height: 15mm-30mm

- Production capacity: ≤1200BPH

- Weight: about580kg

- Dimensions(L x W x H): 2000mm x 1000mm x 1600mm

- Air consumption: 100(Liter / Minute)

- Capping head No.: 1

- Air Pressure: 0.5~0.7 MPA

1. This capping machine is easy to adjust specifications to the size of the drums and bottles.

2. The machine first clamps then caps so capping is precise and thorough. Pneumatic motor driven capping and speed can be adjusted

3. Sensors detect when the number of caps on hold is low

4. Automatic feeding, capping, and dispensing of containers

| No. | name | model ;specification | unit | quantity | note |

| 1 | Modeling socket | Two-hole | unit | 1 | |

| 2 | Breaker | Single-phase, 16A | unit | 1 | CHNT |

| 3 | AC contactor | 0910 | unit | 1 | CHNT |

| 4 | Relay | DC24V; Eight in group | unit | 1 | |

| 5 | Power switch | DC24V;4.2A | unit | 1 | |

| 6 | PLC | S7-200 CN 6ES7 216-2BD23-0XBB | unit | 1 | Siemens |

| Communication link | unit | 1 | |||

| 7 | Touch screen | SA-7B | unit | 1 | Siemens |

| 8 | Transducer | 220V;0.75KW | unit | 2 | Schneider |

| 220V;0.37KW | unit | 3 | Schneider | ||

| 9 | Button | Red | unit | 1 | Schneider |

| Green | unit | 1 | Schneider | ||

| 10 | Emergency | set | 1 | Schneider | |

| 11 | Regulation resistance | 2W10K; add the lip | set | 2 | |

| 12 | Oil-water separator | AW4000 (large) | unit | 1 | |

| AW2000 (small) | unit | 1 | |||

| 13 | Manual slide valve | MS-44MF | unit | 1 | |

| MS-22MF | unit | 1 | |||

| 15 | Fiber amplifier | VRF-N | unit | 2 | |

| 16 | Fiber | NF-TB01 | unit | 2 | |

| 17 | Air pressure switch | HLP-110E | unit | 1 | |

| 18 | Photoelectric Switch | BGS-S08N | unit | 2 | |

| 19 | Minus variable speed motor | NMRV050 0.37KW 1:30 | sets | 1 | |

| 20 | Cylinder | MALΦ32 x 80 | unit | 2 | |

| TN25 x 100 | unit | 1 | Airtac | ||

| DNC-80-40-PPV-A | unit | 1 | Festo | ||

| DNC-80-100-PPV-A | unit | 1 | Festo | ||

| 21 | Vertical motor | YS7124 0.37KW | sets | 1 |