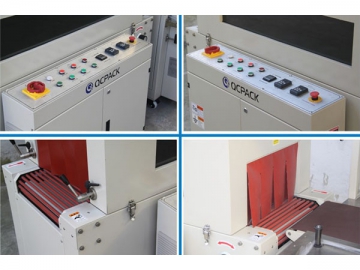

BTH-450 BM-500L

Product Introduction

The fully automatic high speed side sealer and shrink tunnel has an imported PLC automatic program control, easy operations and safety protection/alarm functions to effectively prevent incorrect packaging. The shrink wrap machine is equipped with an imported horizontal and vertical detection photoelectric device, making it easy to switch selections. The machine can be connected directly to the production line with no need for additional operators.

Automatic Grade: Automatic

Driven Type: Electric

Suitable shrink film: POF

Application: food, cosmetics, stationary, hardware, daily used products, pharmaceutical

SamplesTechnical Data: | Model | BTH-450 | BM-500L |

| Max. Packing Size | (L)No limit (W H)≤400 (H)≤150 | (L)No limit x (W)450 x (H)250mm |

| Max. Sealing Size | (L)No limit (W H)≤450 | (L)1500x(W)500 x(H)300mm |

| Packing Speed | 55-60 packs/min. | 0-30 m/min. |

| Electric Supply & Power | 220V / 50Hz 3 kw | 380V / 50Hz 16 kw |

| Max Current | 10 A | 32 A |

| Air Pressure | 5.5 kg/cm3 | / |

| Weight | 800 kg | 400 kg |

| Overall Dimensions | (L)2050x(W)1500 x(H)1300mm | (L)1800x(W)1100 x(H)1300mm |

Product Features:

1. The side blade sealing process is continuous along an unlimited length of a product.

2. Side sealing lines can be adjusted to the desired position based on the product's height in order to achieve excellent sealing results.

3. The shrink wrap machine uses an advanced OMRON PLC controller and touch operator interface. The touch operator interface accomplishes work flow easily, and the panel holding the date memory makes changeovers between products quick and easy by simply calling up the needed date from the database.

4. The entire production is controlled using an OMRON frequency inverter, including feeding, film releasing, sealing, shrinking, and out feeding. The horizontal blade is controlled by a Panasonic servo motor, leaving the sealing line straight and neat. The sealing line is directly down the middle of the product to achieve the perfect sealing effect. A frequency inverter controls the speed of the conveyor, up to 30-55 packs/minute.

5. The sealing knife is an aluminum knife with a DuPont Teflon non-stick coating and high temperature resistance to avoid cracking, smoking and pollution. The sealing balance is equipped with an automatic protection function, effectively preventing accidental cutting.

6. The shrink wrap machine is equipped with a Banner photoelectric device for horizontal and vertical detection to make sealing and packaging of small, thin items easy.

7. The film guide system is manually adjustable, and coupled with the feeding conveyor platform make the machine suitable for items of different widths and heights. When the packaging size changes, the adjustment is easy to carry out. Simply rotate the hand wheel, and no change of molds or bag makers is needed.

8. The BM-500L high speed side sealer uses an advanced circulation blowing process from the bottom of the tunnel. It is equipped with a double frequency inverter that controls the blowing. The blowing direction and volume are adjustable from the bottom.

Parts of the machine Component List

BTH-450 Fully-auto High Speed Side Sealer Component List | No. | Item | Brand | Qty | Note |

| 1 | Cutting knife servo motor | PANASONIC(Japan) | 1 | |

| 2 | product infeed motor | TPG ( Japan ) | 1 | |

| 3 | product output motor | TPG ( Japan ) | 1 | |

| 4 | Film deliver motor | TPG ( Japan ) | 1 | |

| 5 | waste film recycling motor | TPG ( Japan ) | 1 | |

| 6 | PLC | OMRON (Japan) | 1 | |

| 7 | Touch screen | MCGS | 1 | |

| 8 | servo motor controller | PANASONIC(Japan) | 1 | |

| 9 | product feeding inverter | OMRON (Japan) | 1 | |

| 10 | product output inverter | OMRON (Japan) | 1 | |

| 11 | Film deliver inverter | OMRON (Japan) | 1 | |

| 12 | waste film recycling inverter | OMRON (Japan) | 1 | |

| 13 | Breaker | SCHNEIDER ( France ) | 10 | |

| 14 | Temperature controller | OMRON (Japan) | 2 | |

| 15 | AC Contactor | SCHNEIDER ( France ) | 1 | |

| 16 | vertical sensor | BANNER ( USA ) | 2 | |

| 17 | Horizontal sensor | BANNER ( USA ) | 2 | |

| 18 | solid state relay | OMRON (Japan) | 2 | |

| 19 | side sealing cylinder | FESTO (Germany) | 1 | |

| 20 | electrical magnet valve | SHAKO ( Taiwan ) | 1 | |

| 21 | Air filter | SHAKO ( Taiwan ) | 1 | |

| 22 | Approach switch | AUTONICS ( Korea ) | 4 | |

| 23 | Conveyor | SIEGLING ( Germany ) | 3 | |

| 24 | power switch | SIEMENS(Germany) | 1 | |

| 25 | Sealing knife | DAIDO ( Japan ) | 1 | Teflon ( USA DuPont ) |

| No. | Item | Brand | Qty | Note |

| 1 | Infeeding motor | CPG(taiwan) | 1 | |

| 2 | Wind blowing motor | DOLIN(Taiwan) | 1 | |

| 3 | Infeeding inverter | DELTA(Taiwan ) | 1 | |

| 4 | Wind blowing inverter | DELTA(Taiwan ) | 1 | |

| 5 | Temperature controller | OMRON ( Japan ) | 1 | |

| 6 | Breaker | SCHNEIDER(France ) | 5 | |

| 7 | Contactor | SCHNEIDER ( France ) | 1 | |

| 8 | Auxiliary relay | OMRON ( Japan ) | 6 | |

| 9 | Solid state relay | MAGER | 1 | |

| 10 | Power switch | SIEMENS ( Germany ) | 1 | |

| 11 | Emergency | MOELLER(Germany) | 1 | |

| 12 | Heating tube | Taiwan | 9 | |

| 13 | Conveying silicone tube | Taiwan | 162 | |

| 14 | Visible window | High temperature resistant explosion-proof glass | 3 | |

| Model | BTH-450 | BM-500L |

| Max. Packing Size | (L)No limit (W H)≤400 (H)≤150 | (L)No limit x(W)450 x(H)250mm |

| Max. Sealing Size | (L)No limit (W H)≤450 | (L)1500x(W)500 x(H)300mm |

| Packing Speed | 55-60 packs/min. | 0-30 m/min. |

| Electric Supply & Power | 220V / 50Hz 3 kw | 380V / 50Hz 16 kw |

| Max Current | 10 A | 32 A |

| Air Pressure | 5.5 kg/cm3 | / |

| Weight | 800 kg | 400 kg |

| Overall Dimensions | (L)2050x(W)1500 x(H)1300mm | (L)1800x(W)1100 x(H)1300mm |