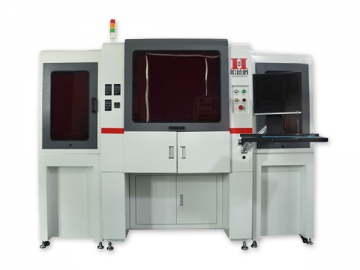

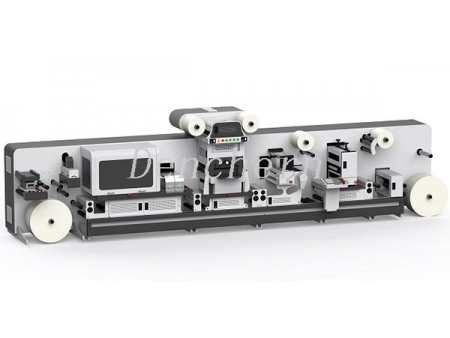

Automatic Die Cutting and Laminating Machine

The new-generation automatic laminating and die cutting machine provides two main functions and is specially developed for the huge demands of FPC (Flexible Printed Circuit) industry. In comparison to commonly-used laminating equipment, the automatic laminator replaces the traditional manual manufacture, improves production efficiency, reduces labor cost, guarantees product quality and brings great economic benefits to enterprises.

The laminating equipment is most often used to paste different kinds of materials onto FPC boards, such as adhesive tapes, stamp gums, stiffeners, thin films, gaskets, electromagnetic film, PI adhesive, cold light panels.

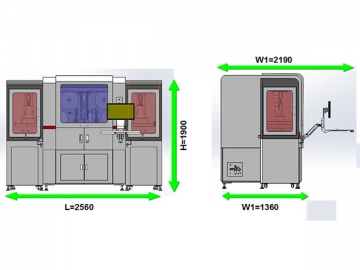

Specifications of Automatic Laminating and Die Cutting Machine| Systems | Items | Parameters | Notes |

| Mechanical system | Dimensions | L 2560mm× W 1360mm × H 2190mm | |

| Workbench size | 500mm × 500mm | ||

| Weight | 1200 kg | ||

| Power supply | 220V 50HZ | ||

| Power | 3KW | ||

| Air source | 0.5-0.8MPa | ||

| Drive system: HIWIN ball screw for X-axis, Y-axis and Z-axis, direct drive rotary motor, rewinding motor, stepping motor for feeding material | |||

| Vacuum sucking platform | Platform surface can be changed depending on the material | ||

| Material feeding and discharging | Mechanical arm | ||

| Rotational angle of platform | 360° | ||

| Laminating precision | ±0.1 | ||

| Repeat accuracy | ±0.1 | ||

| Leftover winding | Imported motor stepping motor | ||

| Locating method | Locating plate vacuum device | ||

| Laminating method | Mold pressing | One-time forming | |

| Laminating speed | 0.3-08s/pcs | ||

| Distance between Z-axis and platform | Can be automatically adjusted according demands | ||

| Software system | Operation system | Microsoft Windows XP Professional | |

| Programming method | Three-point locating, MARK locating, scan locating | Easy and convenient operation, fast response | |

| Operation interface | Easy operation | ||

| Main control system | Computer | Intel dual-core CPU, 2GDDR memory, 500G hard disk | Reliable data process |

| Display | 19-inch color liquid crystal display | Clear display | |

| Control system | Computer control panel | Computer-controlled operation | |

| Visual location system | Camera | CCD pixel: 2 million | |

| Registering | CCD registering, easy and convenient | ≤15min | |

| Light source | Radial pattern light, adjustable luminance | Adjustable dual light source, red and blue | |

Major Features of Automatic Laminating and Die Cutting Machine

1. This laminating system provides automatic FPC feeding and discharging.

2. With the combination of servo motor system and high-precision lead screw for feeding material, the laminator realizes high precision and fast speed.

3. By using a charge-coupled device, the laminating machine accurately locates FPC boards and adjusts the position.

4. During the die cutting process, the automatic laminating machine easily dodges electronic elements on the FPC boards, with fast response speed and large die cutting force.

5. Die cutting molds are easy to change and many types of molds are compatible.

6. Both die cutting workstation and laminating workstation are installed with high-performance safety light curtain to provide protection for operators.

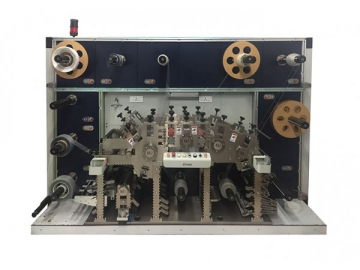

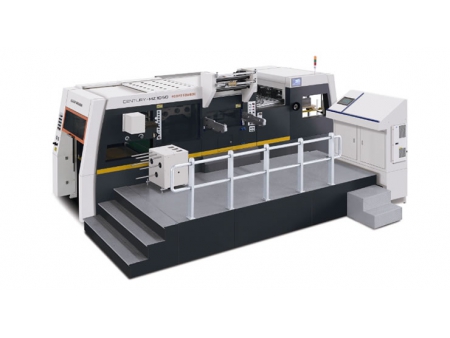

Samples