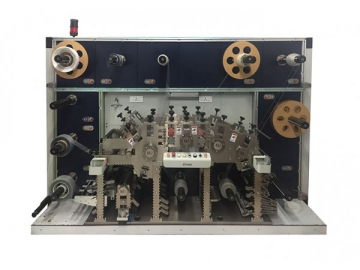

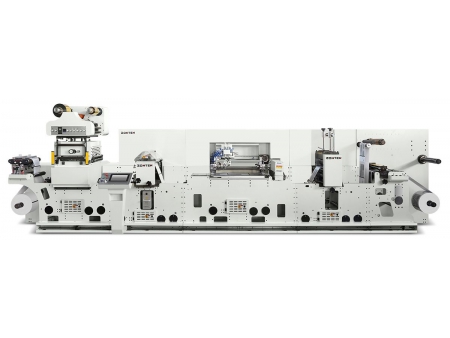

Optically Clear Adhesive Rotary Die Cutting Machine

Touchscreen is more and more widely used in our daily life and has rapidly developed. OCA adhesives are frequently used in the manufacture of cellphone. However, the cutting of OCA products is of difficulty because of the special material properties. Under this context, Hadesheng designed this rotary die cutting machine especially for optically clear adhesives.

Specifications of OCA Rotary Die Cutting Machine| Process | Integrated processing | Asynchronous laminating | Seamless splicing |

| Feature | Integrated processing | Four-strip adhesive laminating | Four-strip adhesive splicing |

| Seam | No | ≥0.15 mm | No |

| Material consumption | 100% | 30% | 35% |

| Qualified rate | 95% | 95% | 80% |

| Machine model | QZDMQ-7-15-250B | QZDMQ-7-15-250B | QZDMQ-8-17-250B |

| Material thickness | ≤1mm | ≤0.5mm | ≤0.5mm |

| Tolerance | ±0.10mm | ±0.10mm | ±0.10mm |

| Process technique | Internationally patented | Patented in China | Patent in China |

| suitable cellphone brands | All cellphone brands | All cellphone brands | All cellphone brands |

Main Features of OCA Rotary Die Cutting Machine

1. The die cutting system can be directly used for OCA adhesives. Many customers give high praise to it.

2. Known for material saving, the rotary die cutter is extensively used in touchscreen manufacture industry.

3. When using the die cutting machine, there is no need to frequently exchange and maintain the release film, thus reducing contamination to the raw material when stripping the film.

4. Different from plain edge die, this type of cutting equipment only causes slight deformation and shrinkage to the optically clear adhesive.

Automatic Waste Discharging

1. OCA leftovers can be automatically discharged.

2. The discharging time is less than one second. In particular, for thin optically clear adhesives, the rotary die cutting system shows a great advantage.

3. Reasonably designed, the discharging device is mounted on the bottom roll. When OCA adhesive is cut off, the raw material will still covered round the bottom roll and stays certain tension, ensuring the adhesive can be quickly removed and discharged.

4. The discharging die is mounted 15 cm above the die and can easily remove OCA leftovers. The die is frequently used when the OCA is thin and easy to tear and the raw material is more than 9 inch thick.

5. The size of discharging die matches well with the die, ensuring the precision and stability of the discharging process.

Protection Measures

1. After wasted materials are removed, a release film must be immediately laminated, reducing the exposure time of adhesive. The release film laminating spindle is about 0.5 meters away from the die.

2. A professional dust-free enclosure is equipped.

Multi-Station Process

1. 3-4 rotary dies can be installed.

2. Other rotary dies can be matched to realize customer requirement for cutting. The final precision can be 0.1mm.

3. Ideal cutting station is designed.

Easy Operation

1. The rotary die cutting machine has a total control over the cutting depth, making the operation easy and convenient.

2. It only takes half a month for an operator to learn how to operate the machine.

3. OCA products and other similar products are applicable for this die cutter.

High Efficiency and Labor Saving

1. The die cutting machine runs in a stable and continuous manner, with a process speed of 30 meters per minute.

2. A process line with plain die requires 3-5 workers while the rotary die cutting machinery only demands one operator.

Fewer Bubbles

According to a test report by a Japanese company, products laminated by the rotary die cutting machine have a qualified rate of 98.8% while products by plain edge die have a qualified rate of 93.2%.