Laminating Film Die Cutter

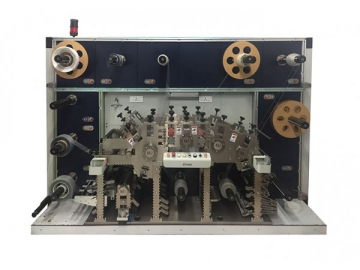

For traditional techniques, cover plates used in scanner and printers are pasted from PP paper. However, before the pasting process, the polypropylene must be pasted with a layer of foam and then coated with a film. All these processes are all done by labors. To resolve the situation and improve production efficiency, Hadesheng researched and developed the laminating film die cutter which pastes PP paper and foam together, coats the two-layer material with film and finally performs die cutting.

The film coating and cutting machine achieves remarkable increase in quality and production and is widely used in the manufacture of foams and other similar materials cannot bear too much intension. Sensors and servo motor are used to ensure stable material feeding and no foam deformation.

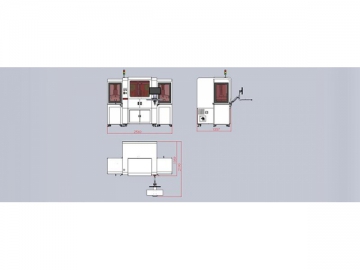

The processes by this laminating film die cutter can be divided into three parts, laminating, coating and die cutting. In general, the multifunctional machine is jointly composed of three units. The unit can be added or reduced depending on the customer’s demand.

Specifications of Laminating Film Die Cutter| No. | Items | Parameters |

| 1 | Production capacity | 20-30 pcs/min |

| 2 | Feeding speed | 15-30 m/min |

| 3 | Workpiece size | 315×230 mm |

| 4 | Machine precision | /-0.5mm |

| 5 | Operator | 1 |

| 6 | Air pressure | 0.6-0.8MPa |

| 7 | Environment temperature | 22-25℃ |

| 8 | Power supply | AC380V 50HZ 11KW |

| 9 | Machine weight | 5000KG |

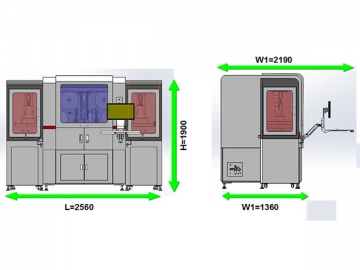

| 10 | Machine dimensions | 5760×1670×2100 mm |

Advantages of Laminating Film Die Cutter

1. An advanced sensor is used to detect the automatic foam unwinding work and will give an alarm when material shortage.

2. Leftover material winding shaft synchronously rotates with the material unwinding material, allowing for synchronous laminating and die cutting.

3. Automatic feeding, laminating and pressing functions are designed.

4. The PP box is suitable for two specifications material while the pressing device is suitable for handling A4-A3 paper.

5. A correcting and adjusting system is installed.

6. The frames of first station and section station can be vertically adjusted according to actual manufacture demands.

7. The material transfer and delivery is all driven by a servo motor, which reduces film deformation and finally guarantees smooth and bubble-free PP paper.

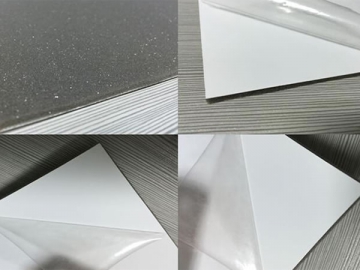

Samples