Block Production Line (Semi Automatic)

Construction of the Block Production Line

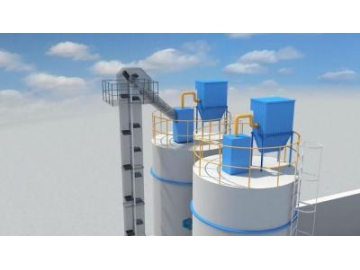

1. Cement Silo

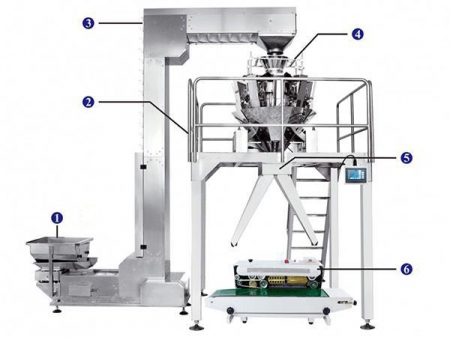

2. Batching Machine

3. Wheel Loader

4. Screw Conveyer

5. Measuring System

6. Pigment Mixer

7. Base Material Mixer

8. Mixing Platform

9. Belt Conveyer for Base Material

10. Belt Conveyer for Pigment

11. Block Making Machine

12. Color Feeding System

13. Computer Control Room

14. Green Block Conveyer

15. Elevator

16. Finger Cart

17. Lowerator

18. Lower Board Conveyer

19. Pallet Cleaning Machine

20. Pallet Turnover

21. Cuber

22. Wood Rack Storage

23. Block Straping Machine

24. Finished Goods to Yard Conveyer

25. Pallet Return Device

26. Industry Overpass

27. Forklift

28. Curing Room

Note: The block production line can be configured with block making machine of models such as Q(F)T10-15, Q(F)12-15, Q(F)18-15 and NM15.

| Type | Volume of Weigh Hopper (m3) | Volume of Unloading Hopper (m3) | Productivity (m3/h) | Maximum Magnitude | Batching Category of Aggregate | Height of Loading Material (mm) | Batching & Discharging mode | Power (kw) | Frame Dimension (mm) | Net Weight (T) |

| PL800 | 2m*2 | 0.8 | 48 | 1.5T | 2 | 2300 | Horizontal | 6.6 | 5470* 1820*2700 | 2 |

| PL1200 | 4m*3 | 1.2 | 72 | 2T | 3 | 2500 | 10.6 | 8531* 2000*2900 | 3.5 | |

| PL1600-3 | 7m*3 | 1.6 | 96 | 3T | 3 | 2900 | 13 | 11650* 2300*3450 | 5 | |

| PL1600-4 | 7m*4 | 1.6 | 96 | 4T | 4 | 2900 | 16 | 15200* 2300*3450 | 7 |

| Type | LJB350 | JS500 | JS750 | JS1000 |

| Charging Volume(L) | 560 | 800 | 1200 | 1500 |

| Discharging Volume(L) | 350 | 500 | 750 | 1000 |

| Productivity(m3/h) | ≥17.5 | ≥25 | ≥37.5 | ≥50 |

| Max. Grain Size of Aggregate(mm) | 60 | 60 | 60 | 60 |

| Speed of Mixing Blade(r/min) | 35 | 35 | 32.6 | 32.6 |

| Mixing Blade(pcs) | 3 | 14 | 14 | 16 |

| Model of Mixing Motor | Y112m-4 | Y180m-4 | Y200L-4 | XWDY9-17-185-6P |

| Power of Mixing Motor(KW) | 5.5 | 18.5 | 30 | 18.5x2 |

| Model of Winch | JS350 | JS500 | JS750 | JS1000 |

| Power of Winch(KW) | 4.5 | 5.5 | 7.5 | 11 |

| Height of Unloading Material(mm) | 1200 | 1500 | 1600 | 2080 |

| Model of Water Pump Motor | 252B21-0.37 | 252B27-0.75 | 65JDB-30 | KQW65-100 |

| Power of Water Pump Motor | 370w | 750w | 1.1KW | 1.5KW |

| Frame Dimension in Working Condition(mm) | 3618×1222×3453 | 4461×3050×5225 | 4950×3636×6530 | 7922×3510×6064 |

| Transporting Frame Dimension(mm) | 1721×1222×2450 | 3050×2300×2500 | 4150×3636×2500 | 4200×3110×2780 |

| Net Weight(T) | 2 | 4 | 6.8 | 9 |

- Double Hoppers

- Single Hopper

| Type | QFT10-15 | |

| Exciting Force (KN) | 100 | |

| Vibration Frequency (HZ) | 0-60 | |

| Power(KW) | 57.88 | |

| Molding Method | Automatic charging, vibrating and pressing | |

| Control Mode | Full automatic PLC control | |

| Molding Cycle(S) | 15-20 | |

| Frame Dimension(mm) | 8700×2500×3020 | |

| Net Weight of Host Machine(T) | 12.2 | |

| Bamboo Pallet | 1220×900×25 | |

| Annual output based on double shift of 300 days | block(m3) | 140,000 |

| paving stone (m2) | 691,000 | |

- Bamboo pallet

- Wooden pallet

Used to carry the block out of the main machine by conveyor. Customers can also choose the PVC pallet or steel pallet.

Note: Bamboo pallet cannot be used for the steam curing system.

- 2)Wood rack Used to carry the block with pallet in the storage yard.

- 3) Wheel loader Used to carry the raw material from storage yard to batching system

Used to carry the finished block to storage yard for curing.

We welcome you to contact us to get further detailed information!