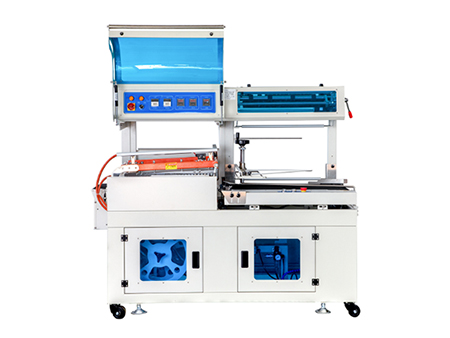

Shrink Packaging Machine

Shrink packaging machine combines an automatic L-bar sealer with a matching shrink tunnel. It can be used as stand-alone machine or added into your existing production lines.

This shrink packaging machine can be used as stand-alone machine or added into your existing production lines.

Model: PPD-450

Usable film: POF/PE film

Sealing speed: 15-30pcs/min

Max. package size (L H): <500mm (H<170mm)

Max. package size (W H): <400mm (H<170mm)

Sealing bar size: 550mm×450mm

Power supply: 220/50-60HZ

Power: 1.35Kw

Machine dimensions (L×W×H): 1650×800×1450mm

Machine weight: 300kg

- Photoelectric sensor is used to automatically detect incoming product;

- Simply place the product onto the sealer, and begin feeding center folded film to wrap around the product by sealing three sides of the bag;

- PID controlled digital temperature control provide accurate and consistent sealing temperature, which can be flexibly adjusted;

- PTFE coated sealing blade is non-stick and resistant to high temperature;

- Built in alloy steel construction, ensuring a robust sealing structure without deformation;

- Automatic feeding of products, the package length can be automatically adjusted by photoelectric sensor;

- Organic glass protective hood with automatic alarming function greatly increase operation safety;

- Film is turned inside out in a 90° manner, providing an efficient production flow;

Model: PPD-4525

Shrink film: POF film

Tunnel dimensions (L×W×H): 1200×450×250mm

Product size: 400×200mm

Feed speed: 0-15m/min

Conveyer: roller chain conveyor

Max. conveyor load: 25kg

Machine dimensions (L×W×H): 1600×700×1520mm

Machine weight: 185kg

Power supply: 380V 50-60Hz

Power: 12kW

- Control panel uses programming system, 12V DC input, button switch and digital display;

- 3P circuit breaker is equipped to protect electrical devices, air volume can be flexibly adjusted by air flow control;

- Height adjustable bracket can be disassembled to accommodate to changing work environments;

- High temperature and wind resistant fabric is adopted to prevent operators form overheating while avoiding the risk of dirt or dust entering;

- Stainless steel guide rails reduce the abrasion of silicone rubber;

- Infrared quartz heating tube offers more stable heating effect;