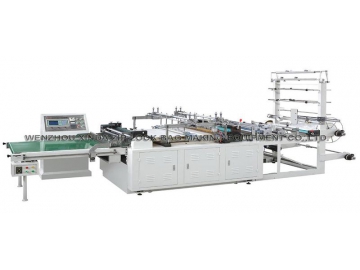

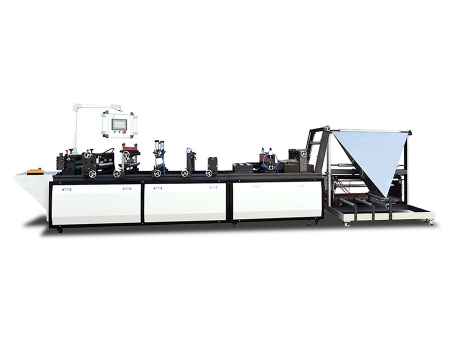

CWZD-400B,CWZD-500B,CWZD-600B Laminated Bag Making Machine

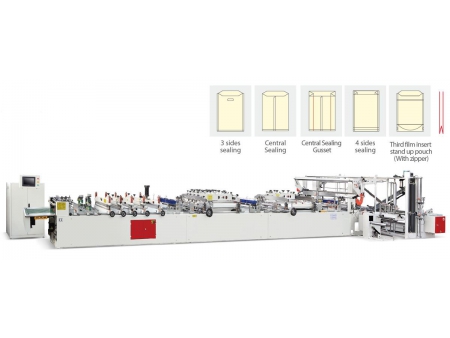

The laminated bag making machine has heavy duty and multiple functions. It is applied to a variety of laminated films to manufacture composite bags including three side sealing type, central sealing type, central sealing with side gusset type, four side sealing type, five side sealing type, stand-up pouch, zipper bag and so on. Additionally, the stand-up pouch has another small non-printed film used for bottom sealing.

Since it is impossible for one bag making equipment to make all kinds of bags, for example, the zipper bag has a different structure with the stand-up and central sealing types, we supply different models of equipment for manufacture of variable bags. The CWZD-B model only works for three side sealing bag, stand-up bag, as well as zipper bag which are commonly employed for food packaging.

Features

1. The laminated bag making machine is matched with 2 servo motors and servo driver which are imported from Japanese Yaskawa for the purpose of traction. In addition, the driving system is regulated by the PLC brought from Japanese Panasonic.

2. All the parameters are presented via the Taiwan produced touch screen characterized by automatic operation.

3. The laminated bag making machine comes with the heavy-duty bridge type heat sealing construction for high sealing intensity.

4. Its unwinding part is attached with the EPC and double photocell tracking system to protect the film being unwound from deviation. The unwinding operation is characterized by automatic tension control.

5. This laminated bag maker owns a 6 skip feeding device.

6. It has an automatic waste film rewinding unit.

7. Moreover, this product can be assembled with a double-layer unwinding unit and handle punching equipment.

| Model | |||

| Unwinding Width | 800mm | 1000mm | 1200mm |

| Pouch-making Length | 70-380mm ×N (N≤ 6) | 70-380mm ×N (N≤ 6) | 70-380mm ×N (N≤ 6) |

| Pouch-making Width | 70-380mm | 70-480mm | 70-580mm |

| Bag Making Speed | 40-160pcs/min | 40-160pcs/min | 40-160pcs/min |

| Film Feeding Speed | 35m /min | 30m /min | 30m /min |

| Total Power | 30kW | 35kW | 40kW |

| Weight | 3600kg | 3800kg | 4000kg |

| Overall Dimension | 10000×1750×1800mm | 10000×1950×1900mm | 10000×2050×2000mm |

Note: Please understand that if we do not inform you of the changes of appearance, performance characteristics as well as technical parameters owing to our consistent improvement of existing products as well as development of new functions.

Related Names

Stand Up Pouch Maker | Stand Up Zipper Bag Making Machine | Stand Up Zipper Pouch Making Machine