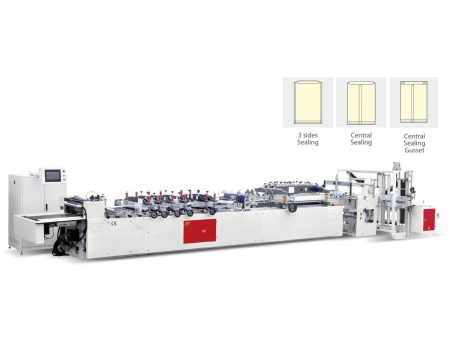

CWZD-400-A, CWZD-500-A,CWZD-600-A Side Seal Bag Making Machine

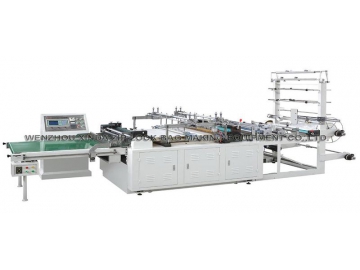

This range of side sealing bag making machine is multifunctional, and is mainly used to make various composite film materials into multifunctional laminated bags, like three side sealing bag, central sealing bag, central sealing bag with side gusset, four side sealing bag, five side sealing bag, etc. Also, it can be used for making stand-up pouch, zipper bag, and more.

Generally speaking, one specific type of bag making equipment can not make all kinds of bags, as the zipper bag has different construction with the stand-up pouch and central sealing bag. To cope with such a problem, we supply equipment in different models to manufacture variable kinds of bags. To be specific, the CWZD-A side seal bag making machine is applicable to three side sealing bag. It can also be used for making central sealing bag, as well as central sealing bags with side gusset. The CWZD-B type is excellent for three side sealing bag, stand-up bag as well as zipper bag. The CWZD-B FS is an ideal choice for three side sealing bag, four side sealing bag, bag with no side sealing, central sealing bag, etc.

Features

1. All the parameters of the central and side sealing bag making machine is displayed on the Taiwan touch screen with a full automatic design.

2. The product is assembled with the EPC and double photocell tracking systems to prevent the film being unwound from deviation of the normal track.

3. All the lubricating points of the product are equipped with the centralized oiling system.

4. Our central and side sealing bag maker possesses 2 sets of servo motors and servo driver which are introduced from Japanese Yaskawa for traction purpose.

5. Its PLC system is imported from Japanese Panasonic.

6. This plastic bag making machinery has a 6 skip feeding device.

7. It comes with an automatic waste edge winder.

8. The machine can be optionally equipped with stand-up pouch device, handle punching unit as well as round angle puncher.

| Model | |||

| Unwinding Width | 800mm | 1000mm | 1200 mm |

| Pouch-making Length | 70-350mm × N(N ≤6) | 70-350mm × N(N ≤6) | 70-350mm × N(N ≤6) |

| Pouch-making Width | 70-380mm | 70-480mm | 70-580 mm |

| Film Feeding Speed | 30m/min | 30m/min | 30m/min |

| Bag Making Speed | 40-170 PCS /min | 40-170 pcs /min | 40-170 pcs /min |

| Total Power | 24kW | 26kW | 28 kW |

| Weight | 3500kg | 3850kg | 4000 kgs |

| Overall Dimension | 8000×1750×1800mm | 8000×1950×1900mm | 8000×2150×1900mm |

| Air Compression | 5HP | 5HP | 5HP |

Note: Owing to our unceasing improvement of existing equipment and development of new functions, the appearance, performance characteristics as well as technical parameters may be changed without further notice.

Related Names

3 Sides Sealing Bag Making Machine | Center Seal Bag Making Machine | Spine Seal Bag Making Machine | Back Seal Bag Making Machine | Pouch Making Machine | Laminated Bag Making Machine