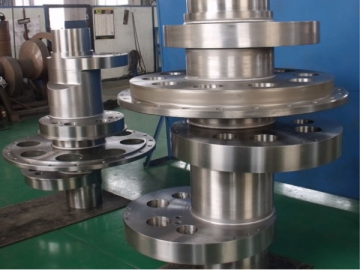

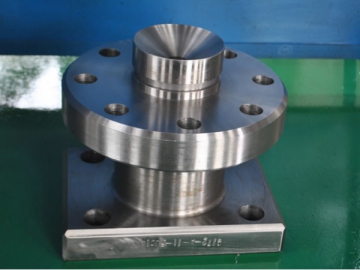

Crankshaft

(Crankshaft for Drilling Mud Pumps)

As a safety component and major transmission part of mud pump, the crankshaft must possess enough stiffness and fatigue strength in order to guarantee reliable working. Given this, our triplex piston pump crankshaft is meticulously crafted according to ABS or BV standard, and it is available in different models to suit for a wide range of F series mud pumps.

Technical Data

| Dimension | Tensile strength | Yield strength | Percentage elongation | Shrink percentage | Average energy | Charpy test temperature |

| 100~300mm | ≥685Mpa | ≥490Mpa | ≥15% | ≥40% | 30J | 0℃ |

| 300~500mm | ≥635Mpa | ≥440Mpa | ≥15% | ≥35% | 30J | 0℃ |

| 500~800mm | ≥590Mpa | ≥390Mpa | ≥12% | ≥30% | 30J | 0℃ |

Feature

1. Our crankshaft could be manufactured from different materials as per customer's needs. Generally speaking, 35CrMo and Q345B are often adopted by F700, F1300 and F1600, while F2000 and F2200 are usually made from 35CrMo.

2. This power end pump part is inherently balanced so as to reduce pressure applied on the bearing and power frame. In this way, the pump power end has a prolonged service life, whilst its maintenance cost and therefore its total operation cost is also cut down. In addition, our product realizes static balance during use, thus leading to low noise level and little vibration.

3. For every crankshaft, its body is constructed from forged high-strength 4130 alloy steel, and its eccentric crescents and gear flanges are produced by our well-skilled front-line workers to ensure the finest quality available.

4. Thanks to our unique design, the fabrication points are away from high-stress areas. As a result, the force applied on our crankshaft is reduced, thus lowering the potential of fatigue cracking.

5. After welding process, comprehensive heat treatment is utilized for the purpose of stress relief and durability improvement. Then, precise machining is carried out, and finally, stringent tests are conducted to make sure that our crankshaft meets the requirements of dimensional tolerance and other specifications. In addition, during the production process, a series of NDT, including ultrasonic testing and magnetic particle inspection, is adopted to examine the quality of weld joint and work piece.