Germany Technology Best Service

Request a Quote

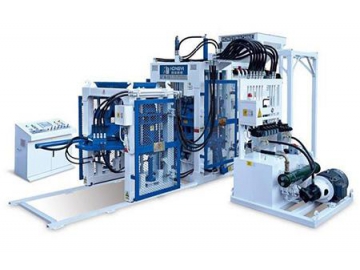

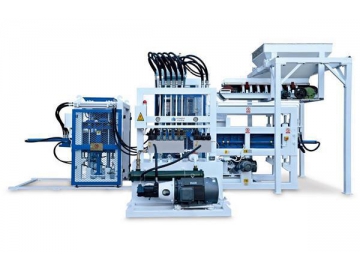

QT9-15 block making machine integrates the merits of QT6-15 and QT8-15 block making machines, and through optimization design, it is easier for the mould platform to arrange the mould layout in order to match with different production lines conveniently. It can be attached with an economic (basic) production line and also suitable for full-automatic production lines.

Features:- Optimized design integrates the merits of QT6-15 and QT8-15 block making machines.

- Siemens control system and four-axis synchronous vibration system can make the machine stable and easy to operate.

- One machine can be multi-purpose and moulds can be changed to produce different types of products such as floor tiles, pc bricks and hollow blocks.

- Either rotational material distribution or horizontal material distribution mechanism can be selected according to specific production requirements.

- Simple adjustment on the lifting mechanism of platform and this is convenient and quick to adjust the height of different products.

| Overall dimension | 5200×2650×2850mm | Vibration method | Synchronous mode of table & mould |

| Pallet size | 1400×750×45mm(Wooden) | Vibration frequency | 50-70Hz |

| Working area | 1300×700mm | Machine Power | 60kW |

| Machine weight | 15600kg | Cycle time | 15s-25s depending on the product size |

| Specification of products (mm) | Number of blocks per pallet | Pieces/hour | Pieces/8 hours | Pieces/300 days (two shifts) | ||

| Block | 400×200×200 390×190×190 | 9 | 2,160 | 17,280 | 10,368,000 | |

| Hollow Brick | 240×115×90 | 25 | 6,000 | 48,000 | 28,800,000 | |

| Paving Brick | 225×112.5×60 | 25 | 6,000 | 48,000 | 28,800,000 | |

| Floor Brick | 200×100×60 | 36 | 8,640 | 69,120 | 41,472,000 | |

| Standard Brick | 240×115×53 | 50 | 12,000 | 96,000 | 57,600,000 | |

Previously made products

Related products

Send Message

Most Recent

More

Other Products

Videos