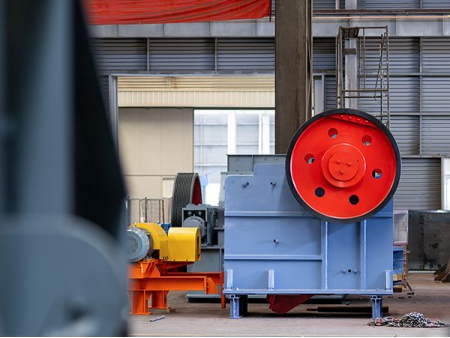

Jaw Crusher

Jaw crushers are primarily used for crushing minerals and rocks with a compressive strength that is not higher than 320MPa, such as limestone, sandstone, shale, gypsum, coal, and clay. The jaw crusher is used in a variety of industries, including mining, smelting, building material, highway, railway, hydraulic engineering, chemical engineering and more.

| Model | Feeding Inlet size(mm) | Max. Feeding size(mm) | Adjustment range of discharge opening(mm) | Processing capacity(m3/h) | Motor power(kW) | Weight (excluding motor) t |

| 500x750 | 425 | 50~100 | 28.5~62.5 | 55 | 10.3 | |

| 600×900 | 500 | 65~160 | 30~75 | 55 | 15.5 | |

| 800×1060 | 640 | 100~200 | 85~143 | 110 | 30 | |

| 900×1200 | 750 | 95~165 | 87~164 | 110 | 50 | |

| 1000×1200 | 850 | 195~265 | 197~214 | 110 | 50.6 | |

| 1200×1500 | 1000 | 150~300 | 250~500 | 220 | 82.3 | |

| 1500×1800 | 1200 | 220~350 | 281~625 | 280 | 122 | |

| 150×750 | 120 | 18~48 | 5~16 | 15 | 3.5 | |

| 250×1000 | 210 | 25~60 | 10~32 | 30 | 6.5 | |

| 250×1200 | 210 | 25~60 | 13~38 | 37 | 7.7 | |

| 300×1300 | 250 | 20~90 | 10~65 | 75 | 11.6 |

Notes: The real capacity of the crusher is affected by many factors, such as the feeding material (material type, material feed size, crushing ability, water content and more), operation (feeding efficiency, feeding distribution), the discharge and other factors. The parameter list can be a reference to the actual usage and productivity prediction.

The jaw crusher uses a crushing chamber with a nip angle. The rotation of the eccentric shaft is driven by a motor through a V-belt, thus causing the pitman to move in line with the eccentric shaft motion, thereby crushing material in the crushing chamber, then transporting it down to be discharged.

Components display

- Tension rod

- Toggle plate

- Adjusting wedges

- Pitman

- Moving jaw

- Cheek plate

- Fixed jaw

- Front frame

When operating, the frame of the jaw crusher will be significantly impact, which means it needs to have a high strength and stiffness. Because of this, the front frame, the back frame and the side frame feature a composite structure.

Pitman

The pitman of the jaw crusher is welded up to reduce the weight. The machining precision is also high enough to operate safely and reliably.

Jaw plate

The jaw plate is the key part for crushing rocks, and includes the fixed jaw and moving jaw. Taking into consideration that this is a highly wearing part, the jaw plate is made from a high manganese steel to ensure it is more wear resistant and has a longer service life. The jaw plate can also be strengthened through a cold hardening process.

- The fixed jaw is fastened on the front frame by wedge bolts to ensure its stability.

- Side guards are installed on the side frame at the both sides of the crusher, which can protect the crusher from wearing when transporting.

- One side of the toggle plate is installed on the adjusting base so that it can hold up the moving jaw. What's more, the mechanical load will increase dramatically and the toggle plate can act as a safety device when the feeding material can not be broken in the chamber.

- The width of the discharge opening can be adjusted by adjusting the thickness of the adjusting wedges.

- The crushing chamber is deep enough to swallow a plenty of raw materials, thus improving the feeding capacity and output.

- With all these different kinds of jaw crusher made by Sinomaly, there is no difference between them but just output. Customizing design and manufacture can be reliable according to your requirements.