Steel Slab / Ingot Continuous Casting Machine(Steelmaking Continuous Caster)

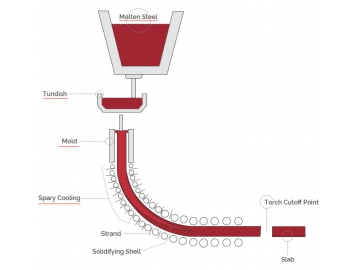

Continuous casting, also called strand casting, is the process whereby heat the metal into liquidation, pour the molten metal into the mold to be solidified to a semi-finished billet for subsequent rolling by the finishing mills. During the casting process, the molten metal is continuously poured into the mold. The mold is available in many sizes and types to cast different sizes of steel billets. When the molten metal pass through the molds at the same rate, different kinds of steel billets are produced base on the shapes of the molds, like square billet, steel slab, round billet and profiled billet.

Among other casting processes like slush casting, centrifugal casting, die casting and sand casting, each process of heating, molten metal into castings, solidification and forging is independent. But in continuous casting process, all the casting processes are completed in one technological procedure. Thus plenty of casting time is saved, helpful to reduce the cost for steel casting. In addition, it contributes to the standardized production of steel casts, resulting in greater quality steel casts.

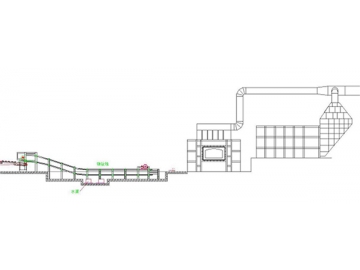

Basic composition of continuous casting equipmentWuxi New Anjie New Energy Co., Ltd produced continuous casting equipment is usually used for the continuous casting of low carbon steel and low-carbon alloy steel. The continuous casting production line is made up of steel ladle turret, tundish, tundish car, mold system, vibration device, secondary cooling device, guiding device, straightening unit and its transmission device, dummy bar storage device, rolling conveyor, billet transfer equipment, cooling bed and other machines. Compared with the traditional die casting, the yield is increased by 10%, with low energy consumption (130kg of standard coal is saved per ton of steel.)

Continuous casting machine can process low carbon steel and low-carbon alloy steel. We can provide different solutions according to users’ needs:

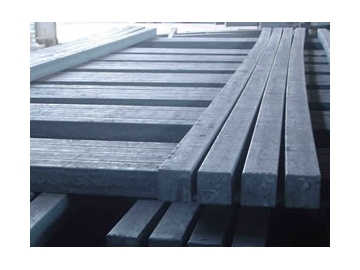

- Square Billet Continuous Casting

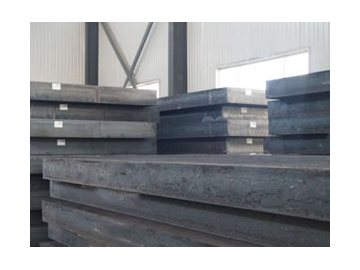

- Steel Slab Continuous Casting

- Round Billet Continuous Casting

Steel Profile Continuous Casting

Steel Profile Continuous Casting

We can design and manufacture the newest continuous casting equipment based on the users’ steelmaking capacity, steel billet size, steel grade and field conditions. What’s more, we are able to do matching for factories with continuous casting equipment.

Customization rangeArc radius of the caster: R2.5-10m

Billet type: square billet, round billet, steel slab, profiled billet

Continuous casting steel billet materials: low carbon steel, low-carbon alloy steel

Designed capacity: 100 thousand tons for 1 straightening unit and one-strand; 200 thousand tons for two straightening units and two-strand; 300 thousand tons for three straightening units and three-strand;