Silicone Sealant Piston Filling Line

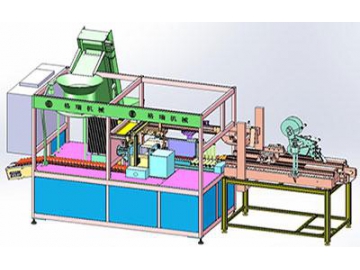

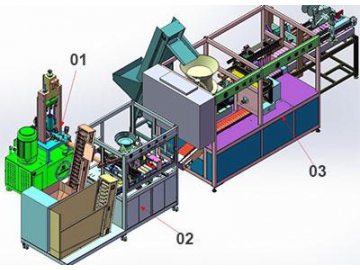

02: material pressuring system

03: dual head piston filler

04: automatic case erector and sealer

02: sealant nozzle storage hopper

03: group A of product cylinders

04: group B of product cylinders

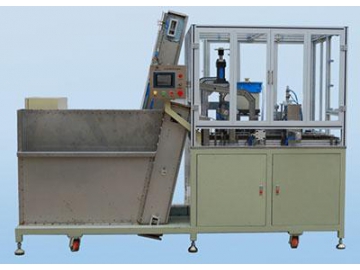

The silicone sealant piston filling machine consists of a 3K static mixer system, material pressuring system, dual head piston filler, plus automatic case erector and sealer. This filling line applies to the batch production of silicone sealant cartridge filling.

| Total power | 45KW |

| Gas consumption | 500L/min |

| Capacity | 1000L/hour |

| Packaging speed | 2-3 boxes/min |

| Color paste proportion | within 8‰ - 8% |

| Additive ratio | within 8‰ - 8% |

| Filling volume | 240-320ML/cartridge |

| Filling accuracy | ±1g/300ml |

| Case size | 5×5 or 4×6 |

| Installation area | 10M (L) ×5M (W) |

Note: We can match the voltage and frequency of the equipment depending on customer location.

This filling line is suited for filling silicone sealant, having the functions of sealant production, filling and packaging. With automatic control, only 3 people are needed for the whole process. This saves labor costs and ensures the qualification rate of the filled products, as well as preventing packaging disorder. If you are interested in this filling line, please contact us. Our professional will contact you to solve your problems in production.