Sheet to Sheet Litho laminating

- Litho Bag

Litho Bag

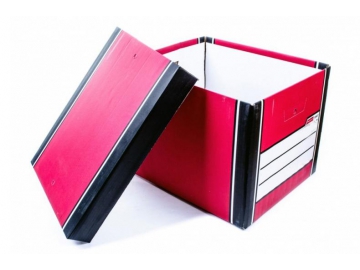

Litho Bag Litho Box

Litho Box Litho Box

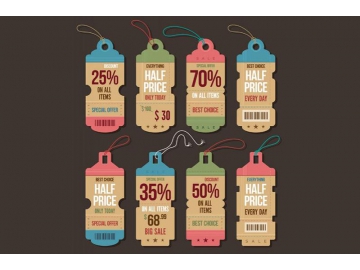

Litho Box Litho Hang Tag

Litho Hang Tag Litho Hang Tag

Litho Hang Tag Litho Art Prints, Framed Art

Litho Art Prints, Framed Art Litho Art Prints, Framed Art

Litho Art Prints, Framed Art

Litho laminating is one of the best methods to mass produce beautiful packaging products along with works of art. After laminating, you will be left with gorgeous end results for products like foldable cartons, litho boxes, hang tags, and home decorations.

Most coversheets with a thickness between 120g – 1000g per square meter and most base materials with a thickness between 250g – 2000g per square meter can be processed using Jialun litho-laminating equipment.

The finished products will be smooth and flat after sheet to sheet laminating. During the gluing process, we find that glue application plays an essential influence on the long term gluing effect. If too little glue is used, the lamination may not stay. If too much glue is used, textures and other defects can appear on the product surface. Our machine is designed to precisely control the glue level and is controlled by a sensor in the gluing unit. Additionally, the gap between the doctor roll and glue applicator can be adjusted manually. Operators can also adjust the gaps according to their own requirements.