Litho Sheet to Board Mounting Laminating

- Litho Laminating Folding Carton

Litho Laminating Folding Carton

Litho Laminating Folding Carton Laminating Corrugated Packaging

Laminating Corrugated Packaging Laminating Corrugated Packaging

Laminating Corrugated Packaging- Litho Foam Board Sign

Litho Foam Board Sign

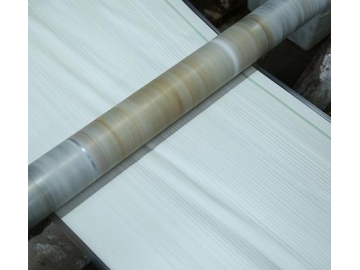

Litho Foam Board Sign Litho Wrap

Litho Wrap Litho Wrap

Litho Wrap

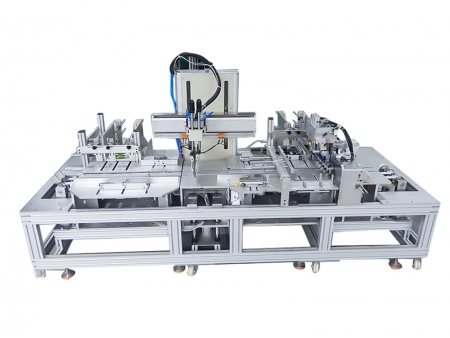

Our litho laminating mounting machines can apply beautiful and smooth coversheets onto the desired substrate. The base materials are typically boards with a certain degree of support ability like cardboard, corrugated board, poly foam board, etc. After lamination, these products can be further processed into foldable cartons, corrugated boards, advertising boards, and decorative pieces.

Most coversheets with a thickness between 120g – 1000g per square meter and most base materials with a thickness between 250g – 2000g per square meter can be processed using Jialun litho-laminating mounting equipment.

To ensure a smooth lamination of sheet to board without any wrinkles, the laminator needs to work with a great deal of precision and accuracy. Therefore, we work to meet the following 3 requirements:

Controlled glue levelDuring the gluing process, we find that glue application plays an essential influence on the long term gluing effect. If too little glue is used, the lamination may not stay. If too much glue is used, wrinkles and other defects can appear on the product surface. Our litho laminating mounting machine is designed to precisely control the glue level and utilizing a sensor in the gluing unit. Additionally, the gap between the doctor roll and glue applicator can be adjusted manually. Operators can also adjust the gaps according to their own requirements.

Smooth base boardAfter being continuously conveyed and stacked, the boards can become bent. To smooth the distorted boards, a sink is installed in the gluing unit. If the base material is bent, water form the sink will help smooth the base materials through roller stacking on the base material.

Suitable feeding speedThere is a servo aligner on the bottom feeder of the litho laminating mounting machine. The servo aligner is designed to synchronize the feeding speed of the base material and the coversheet feeding speed. No matter the speed of the equipment, the alignment needs to remain accurate and the servo aligners delivers an accuracy within ±1 mm.