Rotary Kilns

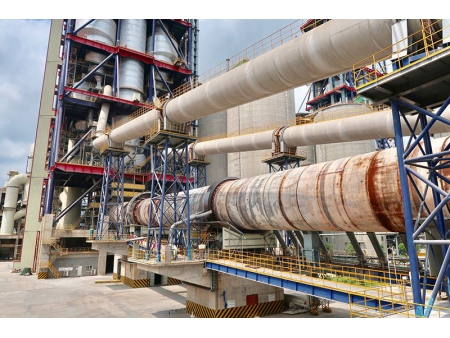

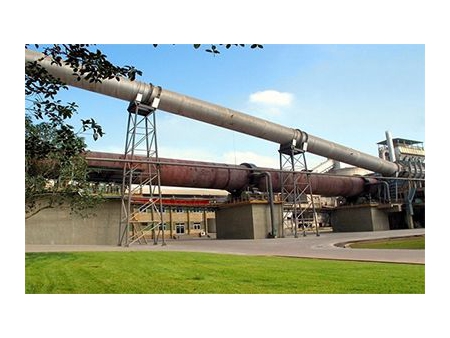

CITIC Heavy Industries (CITIC HIC) has existed now for over 60 years in mineral, agriculture, and other material processing industries. To date, CITIC HIC has designed and manufactured over 1,000 rotary kilns including cement rotary kiln, active limestone rotary kiln, oxidized pellet rotary kiln, non-ferrous metal roasting kiln, rotary kiln incinerator, rotary dryer and more rotary processing equipment which are widely used in construction, metallurgy, non-ferrous metals smelting, active lime, chemical, pulp & paper and other industries. CITIC HIC is dedicated to providing global customers with reliable, energy-efficient and eco-friendly rotary kiln solutions to help them reduce energy consumption, lower low maintenance cost, achieve reliable operation and yield a higher profit.

For the construction industry, CITIC HIC has developed large-scale and super-large-scale rotary kilns that are suited to cement production lines with daily output of 10,000-12,000 ton, the size of cement rotary kiln is up to 6.4m in diameter. When it comes to the metallurgy industry, our pellet rotary kilns cover annual output ranging from 600,000 to 6,000,000 ton. In addition, our two large rotary kilns (Ø7.2×136.5m) designed for coal chemical industry have further refreshed the record of the largest diameter of rotary kiln in the domestic market.

CITIC HIC has successfully engineered 70 types of roasting kiln with different specifications for roasting various metals such as feronikel, aluminum oxide, chromic hydroxide, vanadium salts, zinc oxide, and titanium dioxide, which have been exported to Japan, Malaysia, Indonesia, etc.

From its entrepreneurial beginnings to today, CITIC HIC has been supplying various rotary kilns to serve a number of large domestic companies such as Conch Cement, Tapai Group, TISCO Group, Baowu Group, Chinalco and MCC Group, as well as customers from the global markets including UAE, Thailand, Pakistan, Indonesia, Turkey, Saudi Arabia, South Africa, Algeria, Egypt, Vietnam, etc. Every product we supply is in compliance with international standards during all stages of manufacturing to acceptance. CITIC HIC ranks first in the TOP 20 Enterprises within China Building Material Machinery Industry for its cement rotary kiln technology, and its LK brand cement rotary kiln won the title of China's Famous Brand Products.

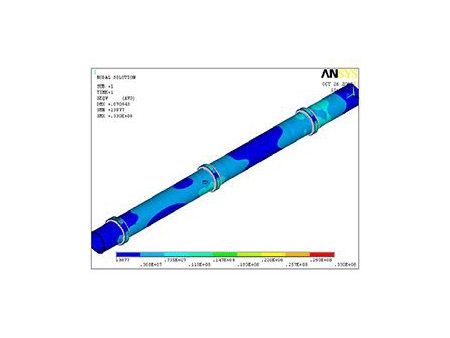

- Strength

-

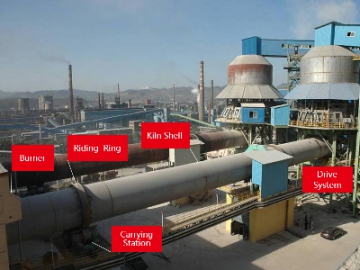

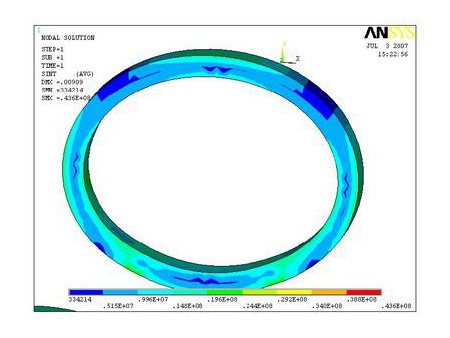

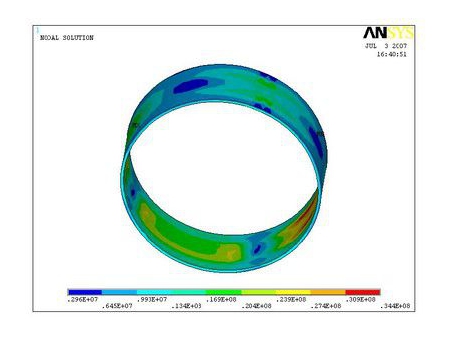

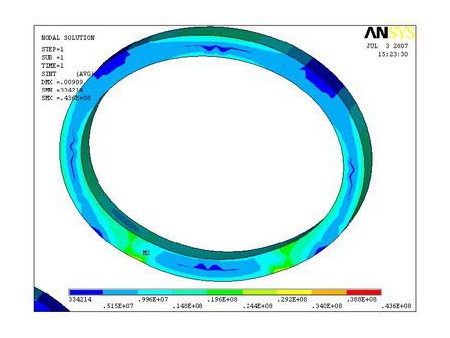

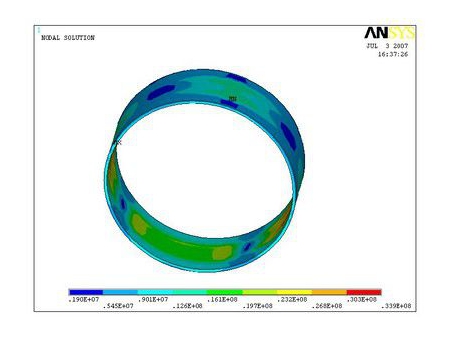

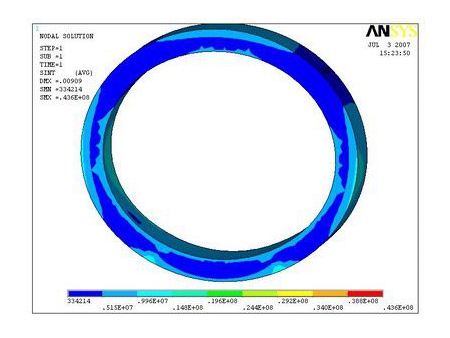

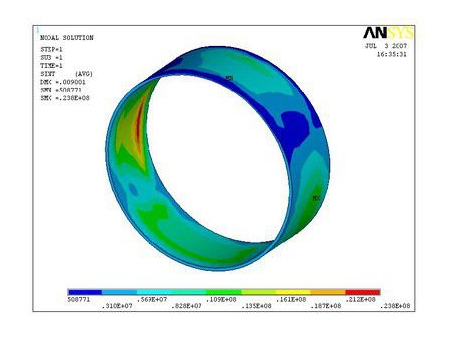

Finite element analysis is employed for strength calculation of kiln drum, kiln tyre (riding ring), support roller, support roller shaft, girth gear, pinion and other key components to identify the optimal structure, and ensure the reliability of the rotary kiln.

More

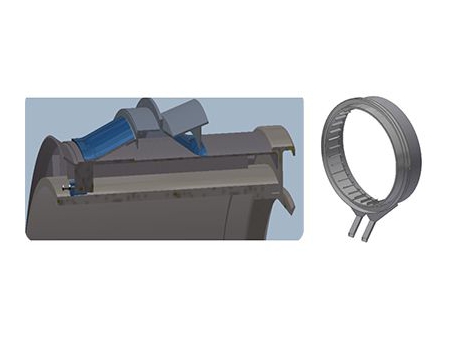

- Filler bars

-

Floating filler bars with double-layer design makes filler bar replacing easier and quicker.

- Kiln inlet & outlet seal

-

Kiln inlet and outlet sealing system combines cold air seal, double leaf seal and labyrinth seal to prevent dust and hot gas from escaping from the kiln.

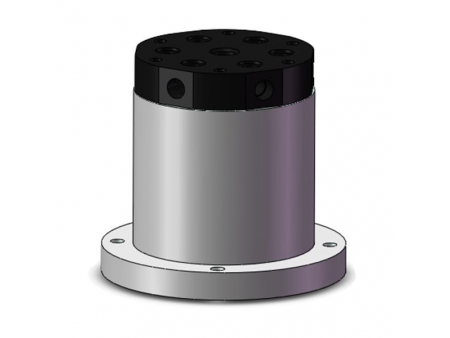

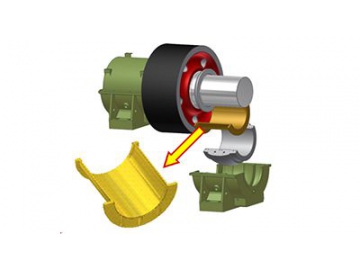

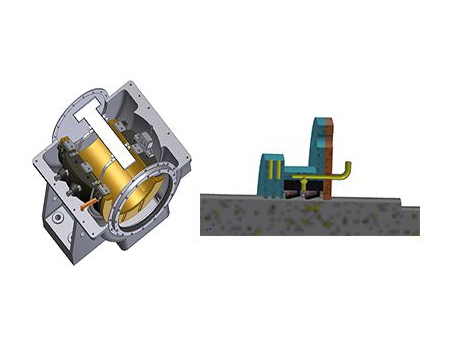

- Kiln support roller unit

-

The design of small contact angle between the roller shaft and bearing bush can help create efficient oil film to improve lubrication effect. The appropriate gap can compensate deformantions caused by heavy loads, thus ensuring the contact between tyre and support rollers to be even.

- Seal structure

-

Deliberate kiln seal design efficiently avoids lubricant leaks.

Rational sealing structure enables an optimal performance and efficiency.

- Lubrication system for support roller unit

-

Support roller bearings are grease-lubricated prior to start-up of the rotary kiln using lubrication system, which can also conduct removal of contaminants, and oil temperature control to prevent bearing temperature form being too high.

| Capacity (t/d) | Internal diameter × length | Remark |

| 5000 | Ø4.8×72m | |

| Ø4.8×74m | ||

| 5500 | Ø4.6×70m | |

| Ø5×74m | ||

| Ø5.2×61m | ||

| 6000 | Ø5×80m | |

| Ø5.2×78m | ||

| Ø5.2×82m | ||

| Ø5.2×74m | ||

| Ø4.8/5.2×74m | Variable diameter rotary kiln | |

| Ø4.8/5.2×76m | Variable diameter rotary kiln | |

| 8000 | Ø4.8/5.6×78m | Variable diameter rotary kiln |

| Ø5.6×78m | ||

| Ø5.6×87m | ||

| 10000-12000 | Ø6×95m | |

| Ø6×90m | ||

| Ø6.2×92m | ||

| Ø6.2×98m | ||

| Ø6/6.2/6.8×92m | Variable diameter rotary kiln |

- Mentioned above are only general specifications, we can customize your rotary kiln according to your specific requirements.

- Rotary kilns of less than 5000t/d in capacity are not listed above.

- Rotary kilns of specifications in between general specifications are not listed above.

Tianrui Group Cement Company

Cement rotary kiln (Ø6.2×92m), daily output 12,000ton

Tapai Group

Cement rotary kiln (Ø6.2×92m), daily output 10,000ton

Anhui Conch Cement

Cement rotary kiln (Ø6×95m), daily output 10,000ton

Turkey Project

Cement rotary kiln (Ø5.6×87m), daily output 8,000ton

Indonesia Hongshi Cement

Cement rotary kiln (Ø5.6×78m), daily output 8,000ton

Myanmar Conch Cement Company

Cement rotary kiln (Ø4.8×74m), daily output 5,000ton

- A wealth of experience in the design and manufacture of rotary kilns

CITIC HIC has 60 years of experience in designing and manufacturing a variety of rotary kilns, over 60 large-scale rotary kilns with diameter of more than 6m. LK brand rotary kilns won the title of "China's Famous Brand Products". - Developing national standards

CITIC HIC has presided over the setting of "Rotary Kiln" standard (JB/T8916-2017, recorded by the Ministry of Machine-Building Industry), and participated in developing standard of "Industrial Cement Rotary Kiln" (GB/T32994-2016). - Low cost

Rational configuration improves energy efficiency and reduces steel consumption. Advanced and reliable intelligent control technology helps achieve low-carbon and eco-friendly operations. - Lifetime customer service management system

Newly established customer service management system enables customers' equipment and spare parts management to be guaranteed round-the-clock, full life cycle.

- Manufacturing

Casting and Forging Capacity

We have four production lines that have the capacity to produce large steel castings, large high-value forgings, large annular parts and large non-ferrous metal parts respectively. - Service

Lifetime service

With state-of-the-art technology and rich experience, CITIC HIC works through each critical step to individualize the optimal process and performance as per customer needs. Our lifetime service covers equipment installation, testing, maintenance, refurbishing, remote monitoring & diagnosis, upgrading & retrofitting, and performance guarantee.