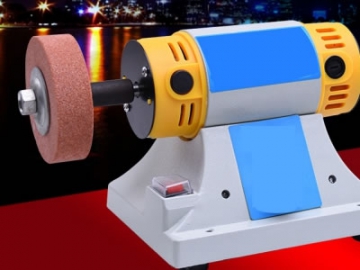

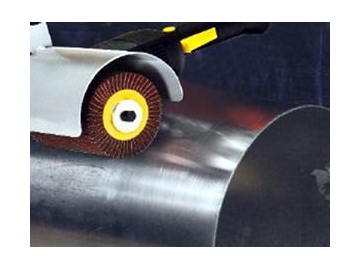

Polishing Wheel (Non-woven Abrasive)

Request a Quote

- The polishing wheel is composed of cellucotton, pigment, glue, plastic cover and sand. The sand material includes alumina oxide, white alumina oxide, black silicon carbide and green silicon carbide. Proportions between each sand type can be adjusted according to different customer needs, and the different materials feature a number of different advantages, as shown below.

Alumina oxide: affordable, sharp

White alumina oxide: sharper than alumina oxide, suitable for metals such as copper and aluminum

Black silicon carbide: abrasive resistant, high toughness, mostly used in soft and brittle materials such as glass, ceramic, stone, cast iron, non-ferrous metals and aluminum alloys.

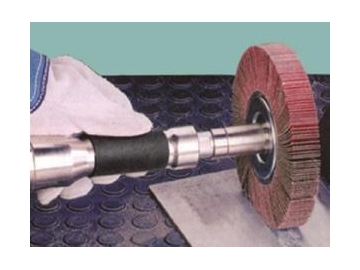

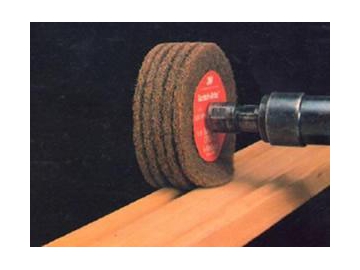

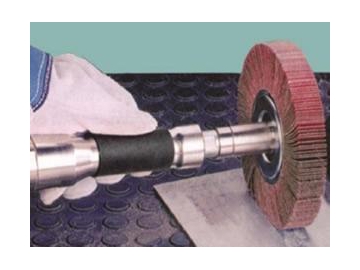

Green silicon carbide: abrasive resistant, good self-sharpening, mostly used in machining hard alloys, titanium alloys, optical glass, stainless steel - The polishing wheel is applicable for metal surfaces polishing and the edge deburring. It is often used for surface polishing and mirror polishing of ceramics, marble, polished bricks and other stone industries. The polishing wheel can also be used for non-metallic surface polishing, such as deburring the furniture, wood crafts, resin crafts and so on.

- We produce polishing wheels in a variety of sizes: 4”, 6”, 8”, 10” and 12”. For different purposes, we can also provide customized wheels according to customer requirements.

Custom polishing wheels:

Sand material: alumina oxide, white alumina oxide, black silicon carbide, green silicon carbide

Plastic backing: white, black

Density: 3P-U00, 4P-U0, 5P-U1, 7P-U3, 9P-U5, 12P-U8。

The higher the density, the harder and more abrasion-resistant the polishing wheel.

Color: brown, red, grey, green

We can engrave customer logos on the plastic backing, as well as customize size and weight according to customer requirements.

- High temperature resistance and high abrasion resistance: We use 66 nylon fiber with a high toughness and high temperature resistance. Its open mesh structure can resist high temperatures, and reduce the risk of deformation and discoloration when the polished object comes into contact with the polishing wheel. It also features a high abrasion resistance.

- Good polishing effect: After the workpiece is processed using the polishing wheel, it will not result in a darker color, and features a high luminance.

- Wide range of application: It can be used for polishing flat objects, concave and convex objects, and objects with grooves.

- Good grinding performance: The polishing wheel will remain sharp no matter how long you use it.

Specifications:

4” Polishing Wheel

| Outer Diameter | Thickness | Inner Diameter |

| 100mm | 12mm | 16mm |

| 100mm | 15mm | 16mm |

6” Polishing Wheel

| Outer Diameter | Thickness | Inner Diameter |

| 150mm | 25mm | 16mm |

| 150mm | 50mm | 16mm |

8” Polishing Wheel

| Outer Diameter | Thickness | Inner Diameter |

| 200mm | 25mm | 16mm |

| 200mm | 50mm | 16mm |

10” Polishing Wheel

| Outer Diameter | Thickness | Inner Diameter |

| 250mm | 25mm | 16mm |

| 250mm | 50mm | 16mm |

12” Polishing Wheel

| Outer Diameter | Thickness | Inner Diameter |

| 300mm | 25mm | 16mm |

| 300mm | 50mm | 16mm |

Related products

Send Message

Most Recent

More

Other Products

Videos